Difference between revisions of "Cast Polyurethane Freestyle Skateboard Bushings"

m |

m |

||

| Line 23: | Line 23: | ||

<gallery widths=500px heights=500px> | <gallery widths=500px heights=500px> | ||

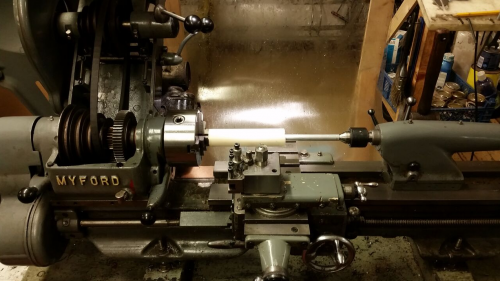

| − | File:Bush1.png| | + | File:Bush1.png|Mounted on lathe with live centre |

| − | File:Bush2.png| | + | File:Bush2.png|Parting tool used to face and surface |

</gallery> | </gallery> | ||

| Line 30: | Line 30: | ||

The bushings are super stable upon initial tests. | The bushings are super stable upon initial tests. | ||

| + | |||

| + | == The Future == | ||

| + | |||

| + | * Testing, testing, testing. Always testing! | ||

| + | * reusable mould designs for bulk production that minimise the amount of finishing required (ideally none!) | ||

Revision as of 14:36, 24 February 2016

Overview

Freestyle skateboarding requires very exact equipment and the choices for truck setup can be particularly exacting. The current favourite off-the-shelf setup is to use Khiro Purple barrel bushings with a conical top and a suitably wide hanger-side washer to prevent "splurge". This setup can be expensive and not so easy to obtain. As part of my ongoing investigations into DIY skateboard equipment and equipment modifications I have developed a prototype truck bushing of the classic stepped Tracker Stimulator shape (design available more recently as Venom Eliminators or Bear Jimz Stepped).

Polyurethane

Two part casting polyurethane is easy to get hold of in small quantities (at a premium price!) but not so easy to find with such exact properties. My thoughts are that if I find a suitable formula then I can buy in bulk to reduce costs.

First Casting Test

Using a two part 72(+/-2) Shore D mix of casting polyurethane in a PVC pipe and laser-cut MDF mould.

The mould leaked somewhat initially as the long pot-life mix was very thin. Adding weights to the base stopped leakage.

Despite using a silicone spray as mould release, the casting had to be cut from the PVC pipe and the dowel was similarly fixed in place.

The finished slug was then mounted on the lathe and a pair of test bushings was cut to size to fit a pair of Independent 109 freestyle trucks.

From the apparent hardness I was expecting the PU to be crumbly and break in chunks on the lathe but it cut very creating lots of paper-like swarf from the parting cutter.

The bushings are super stable upon initial tests.

The Future

- Testing, testing, testing. Always testing!

- reusable mould designs for bulk production that minimise the amount of finishing required (ideally none!)