Difference between revisions of "Electronics PCB manufacture"

| Line 34: | Line 34: | ||

| − | Matt Little has | + | Matt Little has [http://www.re-innovation.co.uk/web12/images/stories/redocuments/information/Nottinghack/Nottinghack%20PCB%20workshop_small.pdf created a page] describing in more details the procedures and processes that he uses regularly for making PCBs using some of the equipment in the Hackspace. |

Short Summary of process | Short Summary of process | ||

Revision as of 15:09, 23 January 2013

| This page is a stub. You can help by expanding it! This page is included in the list of stub pages. |

Equipment that we have

Page in development - need to re-size pics for better display--Dclarke 05:52, 13 June 2012 (EST)

(photo here)

Bubble Etch Tank - on loan from James Fowkes

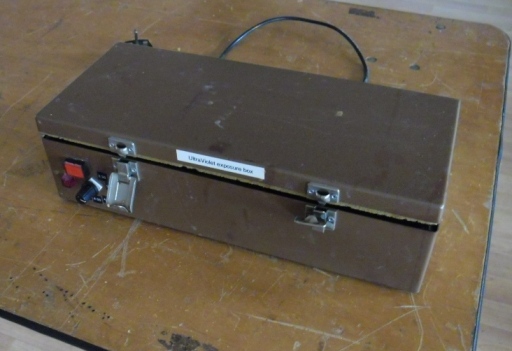

UV exposure unit - on loan from James Fowkes

Lightbox - new addition, hacked from emergency exit light by David Clarke

PCB Drill - Stand on loan from James Fowkes, precision drill on loan from David Clarke

The MaxiCraft drill, from RS has a 12V power pack, but can run on 9-18V d.c. With a suitable 18V power pack, the drill will run at 18000RPM

The chuck capacity is 3.2mm, and there are also some collets (which replace the chuck, which simply unscrews) which can be used with micro drill bits with a 2.5mm shank.

Micro Drills, Collets and Soldering Iron Bits are stored in this small cabinet.

Process and Procedure

Developer, Etching and Tinplating chemistry

Matt Little has created a page describing in more details the procedures and processes that he uses regularly for making PCBs using some of the equipment in the Hackspace.

Short Summary of process

Hints and Tips