Difference between revisions of "Fusion 360"

m (→CNC machines) |

|||

| Line 1: | Line 1: | ||

| − | Fusion 360 is a | + | ==Intro== |

| + | |||

| + | Fusion 360 is a 3D design tool for windows from Autodesk. | ||

It is a very full featured program and also has the ability to convert modeled parts to | It is a very full featured program and also has the ability to convert modeled parts to | ||

gcode which can be run on a CNC machine or to STL parts that can be printed on the 3d | gcode which can be run on a CNC machine or to STL parts that can be printed on the 3d | ||

| Line 7: | Line 9: | ||

To get your Free copy go to the [http://www.autodesk.com/products/fusion-360/overview?mktvar002=685209&mkwid=sV3AFxPXf|pcrid|148576636796|pkw|fusion%20360|pmt|e|pdv|c|&gclid=Cj0KEQiAhNnCBRCqkP6bvOjz_IwBEiQAMn_TMfnHrzIaofTm7fnSiNcBGjuu6_BuXdIHA7y5S43HSSEaAnxT8P8HAQ AutoDesk Web site] | To get your Free copy go to the [http://www.autodesk.com/products/fusion-360/overview?mktvar002=685209&mkwid=sV3AFxPXf|pcrid|148576636796|pkw|fusion%20360|pmt|e|pdv|c|&gclid=Cj0KEQiAhNnCBRCqkP6bvOjz_IwBEiQAMn_TMfnHrzIaofTm7fnSiNcBGjuu6_BuXdIHA7y5S43HSSEaAnxT8P8HAQ AutoDesk Web site] | ||

| − | == | + | ==Modelling== |

| − | + | ||

| + | You can model fully Parametrically in fusion using simple sketches, extrudes, revolves, etc. | ||

| + | There is a very large community of makers using this software and providing excellent tutorials for all of its functionality on youtube so if you don't have any experience at all with CAD I would start there. | ||

| + | |||

| + | ==Technical Drawings== | ||

| + | |||

| + | Fusion has the ability to produce engineering drawings to both ASME & ISO standards; very useful functionality to have for free. | ||

| + | |||

| + | |||

| + | ==CAM== | ||

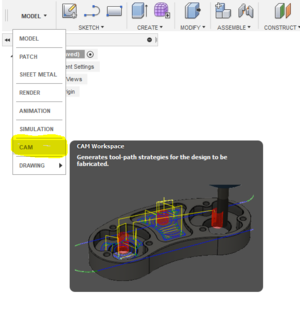

| + | A number of the Hackspace CNC machines ([[Denford Lathe]] and the [[CNC Mill]]) will accept G-Code generated in Fusion 360. Use the CAM workspace to generate tool paths. | ||

[[File:CAM Workspace Fusion360.PNG|thumbnail|none|CAM Workspace]] | [[File:CAM Workspace Fusion360.PNG|thumbnail|none|CAM Workspace]] | ||

| + | ===CNC Mill=== | ||

| − | + | Using the milling tools it is possible to program the [[CNC Mill]] from Fusion. Once your toolpaths have been defined, export the G-Code by post processing using the built in Enhanced Machine Controller settings. | |

| + | |||

| + | [[File:Han Solo Toolpath Simulation.gif|none]] | ||

| − | ==Tutorials== | + | ====Tutorials==== |

| − | There are | + | There are a number of youtube tutorial videos, the NYCCNC ones are rather good. |

The intro one is [https://www.youtube.com/watch?v=o-GBpUZ3piY HERE] | The intro one is [https://www.youtube.com/watch?v=o-GBpUZ3piY HERE] | ||

do a google search for "NYCCNC fusion 360" to find lots more. | do a google search for "NYCCNC fusion 360" to find lots more. | ||

| + | |||

| + | |||

| + | ===CNC Lathe=== | ||

| + | |||

| + | [[User:chriscain|Chris Cain]] wrote up a bit of a how to guide back in 2016 over on the [[Denford Lathe]] page. There are some handy youtube videos documenting his spinning top Manufacture too. | ||

| + | |||

| + | |||

| + | ===3D Printer=== | ||

| + | |||

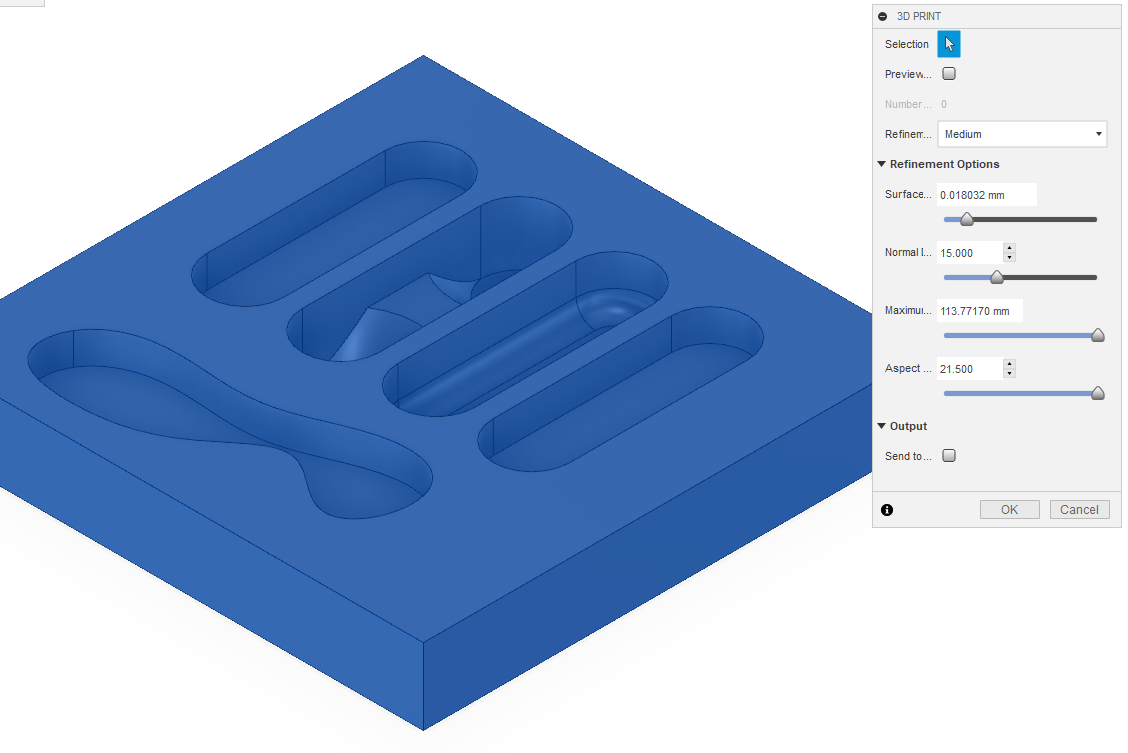

| + | The 3d Printer will also print parts from Fusion360 if they are exported in STL format. | ||

| + | [[File:3D Print output from Fusion.PNG|none]] | ||

| + | |||

| + | ===Laser Cutter=== | ||

| + | You can export any sketch by right clicking it in the feature tree and pressing "Export DXF". This makes it possible to generate laser cutting paths in DXF format from 3D geometry. These can then be imported into [[Laser_cutter#Inkscape|Inkscape]] or directly into [[Laser cutter/LaserCut|LaserCut 5.3]]. | ||

| + | |||

| + | For an example of how this can be used see the [[Les Plywood]] project. | ||

| + | |||

| + | |||

| + | |||

==Recommendations== | ==Recommendations== | ||

Revision as of 12:20, 22 December 2018

Intro

Fusion 360 is a 3D design tool for windows from Autodesk. It is a very full featured program and also has the ability to convert modeled parts to gcode which can be run on a CNC machine or to STL parts that can be printed on the 3d printer.

Installation

To get your Free copy go to the AutoDesk Web site

Modelling

You can model fully Parametrically in fusion using simple sketches, extrudes, revolves, etc. There is a very large community of makers using this software and providing excellent tutorials for all of its functionality on youtube so if you don't have any experience at all with CAD I would start there.

Technical Drawings

Fusion has the ability to produce engineering drawings to both ASME & ISO standards; very useful functionality to have for free.

CAM

A number of the Hackspace CNC machines (Denford Lathe and the CNC Mill) will accept G-Code generated in Fusion 360. Use the CAM workspace to generate tool paths.

CNC Mill

Using the milling tools it is possible to program the CNC Mill from Fusion. Once your toolpaths have been defined, export the G-Code by post processing using the built in Enhanced Machine Controller settings.

Tutorials

There are a number of youtube tutorial videos, the NYCCNC ones are rather good. The intro one is HERE do a google search for "NYCCNC fusion 360" to find lots more.

CNC Lathe

Chris Cain wrote up a bit of a how to guide back in 2016 over on the Denford Lathe page. There are some handy youtube videos documenting his spinning top Manufacture too.

3D Printer

The 3d Printer will also print parts from Fusion360 if they are exported in STL format.

Laser Cutter

You can export any sketch by right clicking it in the feature tree and pressing "Export DXF". This makes it possible to generate laser cutting paths in DXF format from 3D geometry. These can then be imported into Inkscape or directly into LaserCut 5.3.

For an example of how this can be used see the Les Plywood project.

Recommendations

The best part is that Fusion 360 is available for FREE to students/Makers/hobbiests this is great value :-)

There is a lot of information at autodesk, and unusually most of the marketing hype about the capabilities of the program are all true !!.

If you want to make 3d parts this is probably the best software available at a reasonable price you will find!!