Myford lathe/drill and thread charts

Handy drill and thread charts for use with the lathe.

Remember for all drilling operations to use a suitable RPM and drill fluid.

Drill RPM calculations

| Cutting Diameter | Mild Steel | Stainless Steel | Brass/Bronze | Cast Iron | Aluminium | |

|---|---|---|---|---|---|---|

| mm | inch | R.P.M | R.P.M | R.P.M | R.P.M | R.P.M |

| 3 | 1/8 | * | * | * | * | * |

| 6 | 1/4 | * | 2400 | * | * | * |

| 10 | 3/8 | 2200 | 1430 | * | * | * |

| 13 | 1/2 | 1700 | 1100 | * | 2200 | * |

| 20 | 3/4 | 1100 | 700 | 2500 | 1400 | * |

| 25 | 1 | 890 | 570 | 2000 | 1150 | * |

| 32 | 1.1/4 | 700 | 450 | 1600 | 900 | 2000 |

| 38 | 1.1/2 | 580 | 380 | 1300 | 750 | 1700 |

| 50 | 2 | 450 | 290 | 1000 | 570 | 1300 |

| 63 | 2.1/2 | 350 | 230 | 800 | 450 | 1000 |

| 75 | 3 | 300 | 190 | 680 | 380 | 850 |

| 100 | 4 | 220 | 140 | 500 | 280 | 640 |

| 125 | 5 | 180 | 110 | 400 | 230 | 510 |

| 160 | 6 | 140 | 90 | 320 | 180 | 400 |

Where an asterix is used in the table, the required speed exceeds 2500rpm. Simply use a value as close to 2500RPM as possible in this case.

Credit: https://www.greenwood-tools.co.uk/shop/technical-information/cutting-data.html

Center Drills

For any drilling operation on the lathe the Center drill is used first to make the small accurate pilot that the next drill will follow.

They are also use for drilling the required hole when using the live or dead centres.

Use the Highest RPM setting on the lathe!

General rule of thumb is to drill no more than 2/3 up the 60 degree angle

We have 4 Center drill sizes to chose form, BS1 to BS4

For general piloting work the BS3 or BS4 are recommended as the smaller ones are easy to snap.

When supporting work with a live or dead centre lookup the work diameter in the following table to determine the correct drill size and size of the hole needed.

| Gauge | Size (Inches) | Size (mm) |

|---|---|---|

| BS1 | 1⁄8 in | 3.175 mm |

| BS2 | 3⁄16 in | 4.763 mm |

| BS3 | 1⁄4 in | 6.350 mm |

| BS4 | 5⁄16 in | 7.938 mm |

| BS5 | 7⁄16 in | 11.113 mm |

| BS5A | 1⁄2 in | 12.700 mm |

| BS6 | 5⁄8 in | 15.875 mm |

| BS7 | 3⁄4 in | 19.050 mm |

Threading Charts

Metric

The Hackspace has a tap and die set with the following metric coarse sizes

M3 M4 M5 M6 M8 M10 M12

For tapping internal threads use the chart below to select the correct drill size and if needed clearance size for the tap.

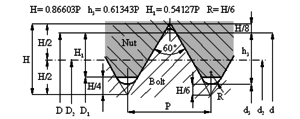

| Nominal Diameter | Pitch | Root Radius | Pitch Diameter | Minor Diameter | Thread Height | Drill Diameter | ||

|---|---|---|---|---|---|---|---|---|

| d = D | P | r | d2=D2 | d3 | D1 | h3 | H1 | mm |

| M 1.00 | 0.25 | 0.036 | 0.838 | 0.693 | 0.729 | 0.153 | 0.135 | 0.75 |

| M 1.10 | 0.25 | 0.036 | 0.938 | 0.793 | 0.829 | 0.153 | 0.135 | 0.85 |

| M 1.20 | 0.25 | 0.036 | 1.038 | 0.893 | 0.929 | 0.153 | 0.135 | 0.95 |

| M 1.40 | 0.3 | 0.043 | 1.205 | 1.032 | 1.075 | 0.184 | 0.162 | 1.1 |

| M 1.60 | 0.35 | 0.051 | 1.373 | 1.171 | 1.221 | 0.215 | 0.189 | 1.25 |

| M 1.80 | 0.35 | 0.051 | 1.573 | 1.371 | 1.421 | 0.215 | 0.189 | 1.45 |

| M 2.00 | 0.4 | 0.058 | 1.74 | 1.509 | 1.567 | 0.245 | 0.217 | 1.6 |

| M 2.20 | 0.45 | 0.065 | 1.908 | 1.648 | 1.713 | 0.276 | 0.244 | 1.75 |

| M 2.50 | 0.45 | 0.065 | 2.208 | 1.948 | 2.013 | 0.276 | 0.244 | 2.05 |

| M 3.00 | 0.5 | 0.072 | 2.675 | 2.387 | 2.459 | 0.307 | 0.271 | 2.5 |

| M 3.50 | 0.6 | 0.087 | 3.11 | 2.764 | 2.85 | 0.368 | 0.325 | 2.9 |

| M 4.00 | 0.7 | 0.101 | 3.545 | 3.141 | 3.242 | 0.429 | 0.379 | 3.3 |

| M 4.50 | 0.75 | 0.108 | 4.013 | 3.58 | 3.688 | 0.46 | 0.406 | 3.8 |

| M 5.00 | 0.8 | 0.115 | 4.48 | 4.019 | 4.134 | 0.491 | 0.433 | 4.2 |

| M 6.00 | 1 | 0.144 | 5.35 | 4.773 | 4.917 | 0.613 | 0.541 | 5 |

| M 7.00 | 1 | 0.144 | 6.35 | 5.773 | 5.917 | 0.613 | 0.541 | 6 |

| M 8.00 | 1.25 | 0.18 | 7.188 | 6.466 | 6.647 | 0.767 | 0.677 | 6.8 |

| M 9.00 | 1.25 | 0.18 | 8.188 | 7.466 | 7.647 | 0.767 | 0.677 | 7.8 |

| M 10.00 | 1.5 | 0.217 | 9.026 | 8.16 | 8.376 | 0.92 | 0.812 | 8.5 |

| M 11.00 | 1.5 | 0.217 | 10.026 | 9.16 | 9.376 | 0.92 | 0.812 | 9.5 |

| M 12.00 | 1.75 | 0.253 | 10.863 | 9.853 | 10.106 | 1.074 | 0.947 | 10.2 |

| M 14.00 | 2 | 0.289 | 12.701 | 11.546 | 11.835 | 1.227 | 1.083 | 12 |

| M 16.00 | 2 | 0.289 | 14.701 | 13.546 | 13.835 | 1.227 | 1.083 | 14 |

| M 18.00 | 2.5 | 0.361 | 16.376 | 14.933 | 15.394 | 1.534 | 1.353 | 15.5 |

| M 20.00 | 2.5 | 0.361 | 18.376 | 16.933 | 17.294 | 1.534 | 1.353 | 17.5 |

| M 22.00 | 2.5 | 0.361 | 20.376 | 18.933 | 19.294 | 1.534 | 1.353 | 19.5 |

| M 24.00 | 3 | 0.433 | 22.051 | 20.319 | 20.752 | 1.84 | 1.624 | 21 |

| M 27.00 | 3 | 0.433 | 25.051 | 23.319 | 23.752 | 1.84 | 1.624 | 24 |

| M 30.00 | 3.5 | 0.505 | 27.727 | 25.706 | 26.211 | 2.147 | 1.894 | 26.5 |

| M 33.00 | 3.5 | 0.505 | 30.727 | 28.706 | 29.211 | 2.147 | 1.894 | 29.5 |

| M 36.00 | 4 | 0.577 | 33.402 | 31.093 | 31.67 | 2.454 | 2.165 | 32 |

| M 39.00 | 4 | 0.577 | 36.402 | 34.093 | 34.67 | 2.454 | 2.165 | 35 |

| M 42.00 | 4.5 | 0.65 | 39.077 | 36.479 | 37.129 | 2.76 | 2.436 | 37.5 |

| M 45.00 | 4.5 | 0.65 | 42.077 | 39.479 | 40.129 | 2.76 | 2.436 | 40.5 |

| M 48.00 | 5 | 0.722 | 44.752 | 41.866 | 42.857 | 3.067 | 2.706 | 43 |

| M 52.00 | 5 | 0.722 | 48.752 | 45.866 | 46.587 | 3.067 | 2.706 | 47 |

| M 56.00 | 5.5 | 0.794 | 52.428 | 49.252 | 50.046 | 3.374 | 2.977 | 50.5 |

| M 60.00 | 5.5 | 0.794 | 56.428 | 53.252 | 54.046 | 3.374 | 2.977 | 54.5 |

| M 64.00 | 6 | 0.866 | 60.103 | 56.639 | 57.505 | 3.681 | 3.248 | 58 |

| M 68.00 | 6 | 0.866 | 64.103 | 60.639 | 61.505 | 3.681 | 3.248 | 62 |

Credit for table: www.tribology-abc.com

For the external threads turn down the work piece to the major diameter.

It is advisable to add a slight chamfer to the right end of the work, to just under the thread minor diameter using the left edge of the cutting tool.