Difference between revisions of "TIG welder"

| Line 1: | Line 1: | ||

| − | [[File: | + | [[File:TIGWelderMiller Dialarc.jpg|thumb|right]] |

Miller Dialarc HF<br/> | Miller Dialarc HF<br/> | ||

TIG (Tungsten Inert Gas) welding is particularly useful for aluminium, It uses an electrode nozzle with a fixed (should be permanent, but they do wear) tungsten tip where a plasma 'flame' is created (started with a high-voltage / high freequency starter) and used to heat the filler wire and joint. The nozzle allows a flow of inert shield gas around the working area, reducing slag creation and (particularly important with aluminium) oxidation. | TIG (Tungsten Inert Gas) welding is particularly useful for aluminium, It uses an electrode nozzle with a fixed (should be permanent, but they do wear) tungsten tip where a plasma 'flame' is created (started with a high-voltage / high freequency starter) and used to heat the filler wire and joint. The nozzle allows a flow of inert shield gas around the working area, reducing slag creation and (particularly important with aluminium) oxidation. | ||

| Line 12: | Line 12: | ||

==Controls== | ==Controls== | ||

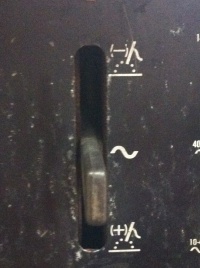

| + | [[File:TIGWelderFrontPanel.JPG|thumb|right]] | ||

Details on the front panel controls | Details on the front panel controls | ||

{| class="wikitable" | {| class="wikitable" | ||

Revision as of 20:18, 11 June 2014

Miller Dialarc HF

TIG (Tungsten Inert Gas) welding is particularly useful for aluminium, It uses an electrode nozzle with a fixed (should be permanent, but they do wear) tungsten tip where a plasma 'flame' is created (started with a high-voltage / high freequency starter) and used to heat the filler wire and joint. The nozzle allows a flow of inert shield gas around the working area, reducing slag creation and (particularly important with aluminium) oxidation.

The TIG welder is a 'stick' welder - the electrode / nozzle is held in one hand, and the filler wire applied with the other.

Shield gas

For the TIG we use a Pureshield Argon.

Capacity and rating

The Tig welder has a large range

Controls

Details on the front panel controls

Tungsten and collets

We have a selection of the following tungsten tips and collets to fit

| Size | Color band | Used for |

|---|---|---|

| 1.6mm | Red | DCEN Steel |

| 2.4mm | Red | DCEN Steel |

| 1.6mm | White | AC Aluminium |

| 2.4mm | White | AC Aluminium |

| 1.6mm | Gold | AC or DCEN, All rounder Steel or Aluminium |

| 2.4mm | Gold | AC or DCEN, All rounded Steel or Aluminium |

Grinding tip shapes

Filler rods

We have the following stock of filler rods

- Steel

- Stainless steel

- Aluminium

- Copper

Power supply

A 63A plug and socket connection is used, with a pushbutton on/off control station and no-volt release.

RFID control of access will be installed shortly.

Tig welding tips

Random collection of useful links