TIG welder: Difference between revisions

No edit summary |

No edit summary |

||

| Line 9: | Line 9: | ||

==Capacity and rating == | ==Capacity and rating == | ||

The Tig welder has a large range | |||

== | ==Controls== | ||

Details on the front panel controls | |||

{| class="wikitable" | |||

|- | |||

! Name | |||

! Picture | |||

! Description | |||

|- | |||

| Main On Off Swtich || [[File:TIGWelderOn Off Switch.JPG|200px]] || Main switch on the welder, remember to turn off the welder as much as possible in-between setting up for welds | |||

|- | |||

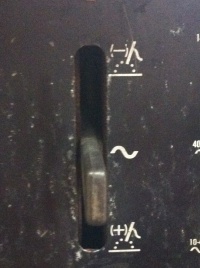

| DC+ AC DC- selector || [[File:TIGWelderDC+ AC DC- Switch.JPG|200px]] || '''Do not change this setting with the main power switch ON.'''<br/> This selector has three positions that control the mode of the welder<br/> | |||

* DC- (DCEN), DC Electrode Negative, used for Steel TIG | |||

* AC, used for Aluminium TIG | |||

* DC+ (DCEP), DC Electrode Positive, used for Arc | |||

|- | |||

| Working power range selector || [[File:TIGWelderWorkingPowerRange.JPG|200px]] || '''Do not change this setting with the main power switch ON.''' <br/>There are three possible working ranges, low, medium and high. Each has a slightly different range for DC or AC | |||

{| | |||

! Position | |||

! AC | |||

! DC | |||

|- | |||

| Up || 140-310 || 125-310 | |||

|- | |||

| Middle || 40-165 || 40-190 | |||

|- | |||

| Down || 10-45 || 10-55 | |||

|} | |||

|- | |||

| Percentage power dail || [[File:TIGWelderPercentagePowerWithinRange.JPG|200px]] || Main power control dial, used to fine tune the amp control of the welder. <br/>This dial acts as a percentage of the current selected range. | |||

|- | |||

|Remote amp control enable||[[File:TIGWelderRemoteAmpageControlSwitch KEEPswitchedOFF.JPG|200px]] || Used to enable remote amperage control when a foot control is installed.<br/> '''Until we have a remote foot pedal this should be left in the OFF position.''' | |||

|- | |||

| High Frequency control || [[File:TIGWelderHF OnAtStrike Off Continous Switch.JPG|200px]] || Controls the high frequency generation of the welder, this switch has three positions and each has a set use.<br/> | |||

*Up (IO) High frequency start, use this for DC TIG welding (Steels) | |||

*Middle (O) Off used for Stick welding | |||

*Down (I) On, used to AC Tig welding (Aluminum) | |||

|- | |||

| Remote trigger enable || [[File:TIGWelderTorchSwitchEnable TIG-on STICKoff.JPG|200px]] || '''This should be left in the ON position.''' <br/> Used to enable the remote trigger, only place in OFF position when doing Arc welding | |||

|- | |||

| Gas overrun timer || [[File:TIGWelderGasOverrunTimer.JPG|200px]] || Controls how long after arc cut off the gas will run for. <br/> Outer scale is tungsten width, inner scale is time in seconds | |||

|} | |||

== | ==Tungsten and collets== | ||

We have a selection of the following tungsten tips and collets to fit | |||

===Grinding tip shapes=== | |||

== | ==Filler rods== | ||

We have the following stock of filler rods | |||

* Steel | |||

* Stainless steel | |||

* Aluminium | |||

* Copper | |||

== | ==Power supply == | ||

A 63A plug and socket connection is used, with a pushbutton on/off control station and no-volt release.<br/> | |||

RFID control of access will be installed shortly. | |||

== | ==Tig welding tips== | ||

Random collection of useful links | Random collection of useful links | ||

* http://www.mig-welding.co.uk/tig-technique.htm | * http://www.mig-welding.co.uk/tig-technique.htm | ||

* http://www.millerwelds.com/resources/improving-your-skills/tig/ | * http://www.millerwelds.com/resources/improving-your-skills/tig/ | ||

* http://www.mig-welding.co.uk/tig-calculator.htm | * http://www.mig-welding.co.uk/tig-calculator.htm | ||

[[Category:Tools_and_Equipment]] | [[Category:Tools_and_Equipment]] | ||

Revision as of 21:14, 8 June 2014

Miller Dialarc HF

TIG (Tungsten Inert Gas) welding is particularly useful for aluminium, It uses an electrode nozzle with a fixed (should be permanent, but they do wear) tungsten tip where a plasma 'flame' is created (started with a high-voltage / high freequency starter) and used to heat the filler wire and joint. The nozzle allows a flow of inert shield gas around the working area, reducing slag creation and (particularly important with aluminium) oxidation.

The TIG welder is a 'stick' welder - the electrode / nozzle is held in one hand, and the filler wire applied with the other.

Shield gas

For the TIG we use a Pureshield Argon.

Capacity and rating

The Tig welder has a large range

Controls

Details on the front panel controls

Tungsten and collets

We have a selection of the following tungsten tips and collets to fit

Grinding tip shapes

Filler rods

We have the following stock of filler rods

- Steel

- Stainless steel

- Aluminium

- Copper

Power supply

A 63A plug and socket connection is used, with a pushbutton on/off control station and no-volt release.

RFID control of access will be installed shortly.

Tig welding tips

Random collection of useful links