Bambu Lab P1S

| Bambu Lab P1S | |

|---|---|

| |

| Manufacturer | Bambu |

| Model | P1S |

| Location | 3D Printer Area |

| Team | 3D Printing |

| Induction Required | No |

| Risk Assessment | Yes, see the assessment |

| Tools: all pages • list • Power Tools • Broken tools {{}} | |

This printer was installed in the Space on 16th July, 2025.

For a guide on how to 'slice' 3D models to prepare them for 3D printing, please see How To: Slice Models For 3D Printing

Buying Filament

The P1S takes 1.75mm filament, so choose some PLA or PETG in your favourite colour.

The nozzle in the P1S uses a 0.4 hardened nozzle and can use filaments that contain "fillers" such as Carbon fiber or glow in the dark.

PETG prints well, is tougher than PLA but can create strings if printing too fast - is better than PLA when coming into contact with water and will resist higher ambient temperatures than PLA.

PLA gives good detail and clean prints - is brittle and is not good to use in moist conditions - it will also tend to misform in high ambient temperatures.

You can buy branded Bambu filament off the Bambu store, or just shop about on online marketplaces or wait until we do a Bulk buy and hop onto that.

WARNING: TPU loves to grip onto build plates - especially the PEI plates (which is the gold one on the printer). It is highly recommended to apply a thin layer of glue stick (pritt et al) to the print plate before printing to prevent the TPU "welding" itself to the plate ruining it.

P1S screen display

The display on the P1S is (annoyingly) retro.

The detailed explanations of functionality are out of scope for this page but you should inform yourself of the screen options by using the link below.

https://wiki.bambulab.com/en/p1/manual/screen-operation

Preparing the machine to print

Check your filament is loaded.

Load your filament by going to:

Nozzle icon > Feeding > Load

The printer does not ask for the type of filament and chooses a generic nozzle temperature.

Check that the build plate is correctly positioned.

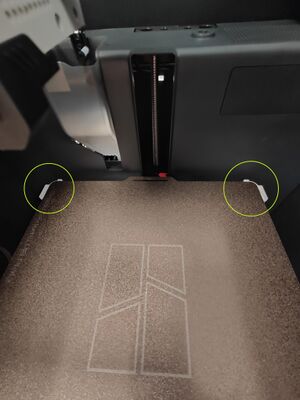

Check build plate positon

This is essential before you begin printing.

The back of the build plate must be between the plastic tabs.

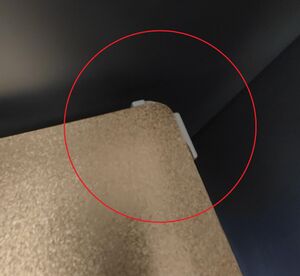

If care is not taken it is possible to place the build plate on top of the plastic guides without realising because you cannot easily see inside the chamber.

Check with your finger that the plate is not sitting on top of either of the tabs.

The plate is not seated correctly and will probably result in the print head hitting and damaging the plate and head Check with your finger that the plate is not sitting on top of either of the tabs.

There is a detailed breakdown of steps for getting things up and running on this page:

Printing direct to the printer from the slicer

You have to be connected to the LAN in Hackspace and be able to "see" the P1S. If you cannot see the printer you may need to adjust your firewall settings.

In preview tab of the slicer choose "Print plate", this will Send the sliced code to the printer and the print job will begin.

Printing from a Micro SD card

You will need to have saved your sliced part to a Micro SD card.

In "Preview tab" of the slicer, choose the dropdown from "Print plate" and select "Export plate sliced file"

Click this and you will be prompted to save the file in a name format yourname_m.gcode.3mf.

Put this file on your Micro SD card and head off to Hackspace.

Insert your Micro SD card into the P1S, and navigate to the folders tab your sliced object file name will be shown on the P1S display. REMEMBER TO REINSERT THE ORIGINAL SD CARD AFTER YOUR PRINT HAS FINISHED

Choose the files and hit OK.

Printing operation

The printer will go through its startup routine (which includes auto bed levelling), a little shaking too.

A purge line will be printed on the front of the build plate.

When the print is completed - wait a few minutes for the build plate to cool down and then it should be very easy to remove your printed item.

Please try not to use scrapers or tools that might damage the PEI print plate material

Cleaning up

Unload your filament by going to:

Nozzle icon > Feeding > Unload

Follow the instructions.

Ensure the build plate is free of your printed item, supports and any filament purge lines (found at the front of the build plate).

If your print does not want to stay put on the build plate during printing

Sometimes first layers don't seem to want to "stick" to the build plate. This is usually due to grease/dirt from fingers previously touching the build plate.

To try and remedy this:

- using a little washing up liquid and water (not soap)

- wash the plate

- rinse with clean water

- dry the plate with a paper towel

This tends to solve 99% of bed adhesion issues. The sink in the Blue Room next to the 3D printer area has all you need to wash the plate.

Note: there are no manual adjustments on this printer (unlike older printers) so please don't try and tinker - contact the 3d printing team if you have issues.