WW2 Prop Gold: Difference between revisions

Created page with "{{Project |image=File:WW2 Prop Gold (1).jpg |name= |primary=Nick |created=09/03/2019 |completeddate=28/03/2019 |dormantdate= |version= |members=Dan |sta..." |

mNo edit summary |

||

| (3 intermediate revisions by the same user not shown) | |||

| Line 14: | Line 14: | ||

}} | }} | ||

Nick needed to make some fake WWII gold for an escape room game. Brass | Nick needed to make some fake WWII gold for an escape room game. Brass was used as the material so that bars had some heft to them. Each bar weighs approximately 800g but feels satisfyingly heavy. | ||

The toolpaths were produced using Fusion 360. The reference model was taken from thingiverse: https://www.thingiverse.com/thing:2442031 | The toolpaths were produced using [[Fusion 360]] and cut using the [[CNC Mill]]. The reference model was taken from thingiverse: https://www.thingiverse.com/thing:2442031 | ||

The first operation was done with a 6mm flat end mill. The 2D Adaptive option was used to give a smooth cut with 1mm optimal load and 1mm depth cuts. | The first operation was done with a 6mm flat end mill. The 2D Adaptive option was used to give a smooth cut with 1mm optimal load and 1mm depth cuts. | ||

The second operation was done using a 1.5mm ball | The second operation was done using a 1.5mm ball nose tool. Parallel passes were used to produce the text with good results. The only problem with this approach is that the cross hatched tooling marks are plainly visible on the surface. | ||

==Gallery== | ==Gallery== | ||

Latest revision as of 08:09, 28 March 2019

| WW2 Prop Gold | |

|---|---|

| |

| Primary Contact | Nick |

| Created | 09/03/2019 |

| Completed | 28/03/2019 |

| Members | Dan |

| Status | Complete |

| Type | Members Project |

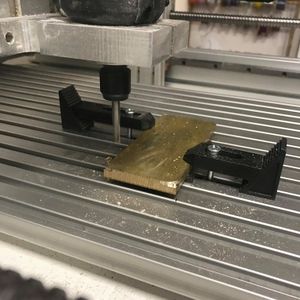

Nick needed to make some fake WWII gold for an escape room game. Brass was used as the material so that bars had some heft to them. Each bar weighs approximately 800g but feels satisfyingly heavy.

The toolpaths were produced using Fusion 360 and cut using the CNC Mill. The reference model was taken from thingiverse: https://www.thingiverse.com/thing:2442031

The first operation was done with a 6mm flat end mill. The 2D Adaptive option was used to give a smooth cut with 1mm optimal load and 1mm depth cuts.

The second operation was done using a 1.5mm ball nose tool. Parallel passes were used to produce the text with good results. The only problem with this approach is that the cross hatched tooling marks are plainly visible on the surface.

Gallery

-

Corners rounded over with a 6mm bit

-

Wooden test piece with the brass piece

-

How the gold bar looks prior to polishing

-

Polishing the lettering with the dremel