Bat Box: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| Line 26: | Line 26: | ||

#Mark out the wood with a marker pen or pencil | #Mark out the wood with a marker pen or pencil | ||

#[[Table Saw]] to do the majority of the cuts. | #[[Table Saw]] to do the majority of the cuts. | ||

#For the side pieces with angled tops, I used the [[Sliding | #For the side pieces with angled tops, I used the [[Sliding Mitre Saw]]. | ||

#Hand Miter Saw to do the 1mm deep bat ladder on the back piece. | #Hand Miter Saw to do the 1mm deep bat ladder on the back piece. | ||

#[[Cordless_Drills|Impact Driver]] to screw everything together. | #[[Cordless_Drills|Impact Driver]] to screw everything together. | ||

Revision as of 08:16, 12 July 2019

| Bat Box | |

|---|---|

| |

| Primary Contact | Danspencer101 |

| Created | 23/06/2019 |

| Completed | 23/06/2019 |

| Status | Complete |

| Type | Workshop Activity |

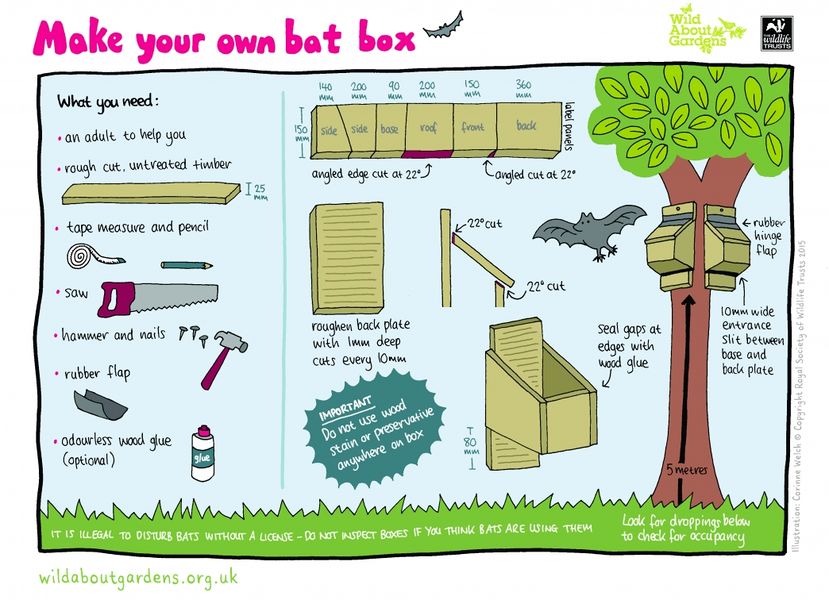

I had a go at making a Bat Box from plans on the Nottinghamshire Wildlife Trust website.

The wood (6" x 1" x 1200mm) was obtained from Harlow Bros. It can be brought in 4m-ish lengths for around £7. They cut it down for free into three manageable lengths that would fit into my car.

-

Plans from the Wildlife Trust Website

Method

The method of manufacture is as follows:

- Mark out the wood with a marker pen or pencil

- Table Saw to do the majority of the cuts.

- For the side pieces with angled tops, I used the Sliding Mitre Saw.

- Hand Miter Saw to do the 1mm deep bat ladder on the back piece.

- Impact Driver to screw everything together.

- Laser Cutter to engrave logos.

- Seal gaps with wood glue.

Gallery

-

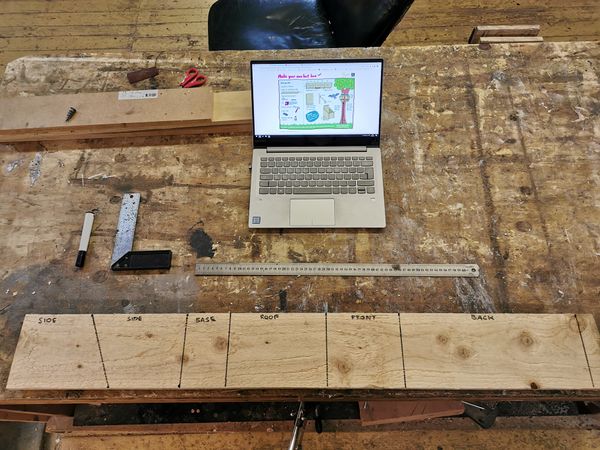

Marking out the cuts

-

Marking out the cuts

-

The finished bat box

-

The finished bat box

Workshop July 2019

<gallery mode=packed-hover heights=300px> File:BATBOX1.PNG File:BATBOX2.PNG <gallery>

Also available as a PDF File:BatBox Workshop.pdf