Laser Cut COVID-19 PPE: Difference between revisions

No edit summary |

|||

| Line 100: | Line 100: | ||

Q. Should I make shields if no one has said they want them in my area?<br> | Q. Should I make shields if no one has said they want them in my area?<br> | ||

A. They may be needed later, and desperately, the decision is yours, right now, many clinics aren't sure what they'll need or what they'll be able to get hold of if cases continue at the current predicted rates.<br> | A. They may be needed later, and desperately, the decision is yours, right now, many clinics aren't sure what they'll need or what they'll be able to get hold of if cases continue at the current predicted rates.<br> | ||

==Other groups working on similar items== | |||

We are looking for design and maufacture locally to Nottingham, UK. Thee are lots of other people working on similar ideas. They are linked here for info: | |||

* [https://github.com/DoESLiverpool/covid19 DoES Liverpool] | |||

* | |||

Revision as of 15:29, 28 March 2020

This page summarises the effort by members to produce and supply laser cut personal protective equipment (PPE) for NHS staff in response to the current COVID-19 situation.

This page is a NO BIKESHEDDING ZONE and should only be used for co-ordination of the manufacturing and distribution effort. PLEASE READ THE FAQ HERE BEFORE ASKING QUESTIONS

Safety & Hygiene

Please do not compromise your own safety, or that of others, in order to obtain materials or access printers / laser cutters. Follow government guidelines and stay at home. We must ensure that no risks at all are taken.

We must ensure as much as possible that the PPE/parts come from COVID-19 free homes/workshops, handled as little as possible and, if needed, are handled in a hygienic way. If that is not the case then anything produced is not any use. If you or anyone in your household COVID-19 symptoms (however mild) or are self-isolating then any parts you supply could be an infection risk and will not be useful.

Before and after handling materials ensure you wash your hands following WHO guidance. Use sterile gloves & face mask during production, if at all possible. See more details about reducing contamination in the FAQ, below.

Collaboration & Points of Contact

We have been working with Kitronik and Smoke & Mirrors to create a laser cut version of the RC1 & RC2 Face Shield for use by at risk, front line medical staff. Due to the scarcity of materials suitable to make an entire face shield in a single laser cut, we’ve adapted a 3D printed design, already accepted by (our local GP alliance &) the NHS in the UK as suitable.

DrGandalf on Slack is our NHS contact.

Geoff Hampson, one of the directors at Kitronik, is also on the Slack channel. He may be able to help with manufacturing and material supply.

Laser Cut Face Shields with Acetate Sheet Front

Please check out the most up to date information here on Smoke & Mirrors community site.

Here is the DXF File for laser cutting a Polypropylene (PP) head band to attach an A4 clear binder cover sheet to:

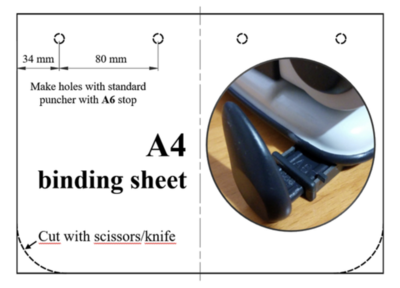

NOTE - THIS IS VERSION 0.4 which DOES NOT REQUIRE A FOUR HOLE PUNCH - IT USES A TWO HOLE PUNCH AS PER PICTURE BELOW:

THINGS YOU WILL NEED:

- 1. A Laser Cutter with bed greater than A3 300mm x 400mm

- 2. Polypropylene sheet 0.5mm any colour This for example

- 3. A4 clear acetate/PVC binder cover (This will NOT be laser cut - use the hole punch)

- 4. Hole punch with slider for A6 holes (current version needs a 4 hole punch for A4).

- 5. Clean hands and a way to bag you shields

PLEASE READ THE FAQ HERE BEFORE ASKING QUESTIONS

The shield consists of 2 parts.

- A Polypropylene (PP) adjustable head band, this is laser cut from 0.5mm polypropylene sheet of ANY COLOUR like this at Kitronik

- An A4 PVC or Acetate Clear Binder Sheet at least 100 microns thick as used for binders and other publications similar to this on Amazon

Notes about the shield:

The plastic sheet acetate/PVC This DOES NOT need to be laser cut. Use a hole punch on the A6 setting to make holes on either end of the sheet to attach to the polypropylene head band. We will make a set of pictures of a video showing this later.

The above linked sheet are rapidly becoming a low supply item, it is worth searching around the web for something similar from a different supplier or even try your local BIG STATIONARY STORE especially if they have an online dept. Or you could email or call them.

Seems to cut one headband out of PP in around 1 min 30 seconds. Power 22, Speed 70 (Kitronik laser settings YMMV).

PLEASE READ THE FAQ HERE BEFORE ASKING QUESTIONS

3D Print Face Shields with Acetate Sheet Front

Please see this page for information and designs for the 3D-printed version

Laser Cut Face Shield FAQ

Please read this FAQ

Q. Is this design suitable/safe/certified/clinically acceptable?

A. Medical Practitioners have told us "the visor acts to protect the wearer from droplets/aerosols and splashes emanating from a patient's airways. The wearer therefore will already be utilising precaution (hand washing/gloves/correct procedures etc) so risk is very low and becomes theoretical rather than real when one judges risk/benefit to the wearer, the patient and subsequent patients." and "My recommendation to workforce will be this is equipment for additional protection that is not certified.

So far not had anyone said no given our current supplies."

Q. What anti-contamination process should we follow?

A. Wash your hands, wipe down the material before cutting. Wear a mask if you have one, or one of the shields. One of our RAMC/NHS contacts said "Regarding Anti contamination: The theoretical risk is that one of you doing this work has viral particles/droplets on your hands as you handle the product as it's being manufactured. Or indeed it has been supplied to you already in this state. We have some evidence of persistence of infectious particles remaining on surfaces for prolonged times. (I'm sure that is exactly why you are asking the question by the way). So what? In reality, the visor acts to protect the wearer from droplets/aerosols and splashes emanating from a patient's airways. the wearer therefore will already be utilising precaution (hand washing/gloves/correct procedures etc so my opinion is that risk is very low and becomes theoretical rather than real when one judges risk/benefit to the wearer, the patient and subsequent patients."

Q. Why don't you just make the design out of one piece of materials?

A. We have been unable to source suitable material in bulk.

Q. I've made a better design, use it instead.

A. Thank you, you might want to take some photos and let us know about it, but part of the challenge here is allowing health care official the time to consider iterations. They're busy with other things and seem to respond best to existing items (not theoretical ones) and consistency of offer. "This one is good... we'd like more of this."

Q. I know such and such a place or person with a laser cutter, you should contact them for me please?

A. No, please reach out to them yourself. We're busy making shields and fielding questions and organising what we can. If you don't personally have access to a laser cutter, you may not be the decision maker needed to help with this task. Thank you but sorry. We are not able to arrange access to a laser cutter for you, no matter how keen you are.

Q. I have a laser cutter of about A5 or A4 size.. can I help?

A. We're not sure. This task is probably better suited to cutters at least A3 and up in bed size thats greater that 300mm x 400mm, Polypropylene can also be tricky to cut if you've not cut it before.

Q. Where can I find the cut file/latest cut file?

A. Currently we have it on this forum post at Smoke & Mirrors Community

Q. Who are you liaising with?

A. This is a good question. We've been dealing with Dr Ghandi of the Nottingham GP Alliance https://www.ncgpa.org.uk/ who is now liaising directly with Dominic Morrow as the SLACK is too noisy to effectively communicate to the group that way. We have also contacted the NUH https://www.nuh.nhs.uk/ currently there is demand for 3D printed version of the RC3 remix face shield https://www.prusaprinters.org/prints/26241-face-shield-a4-binding-sheet-easy-punching-rc1-and and a perhaps lower level of trust of the as yet, unseen laser cut shield.

Q. Do they actually want this stuff?

A. Busy health care doctors and administrators don't want to be bothered with a lot of questions and decision making that they might have to pass up the line or that they may feel goes against the systems the NHS and other practices have put in place. Ad hoc improvised face shield, we are told, are needed, but we have encountered uncertainty at some levels and parts of what is an over stretched and somewhat pre-occupied organisation. Push on regardless, the shields will be needed!

Q. Should I make shields if no one has said they want them in my area?

A. They may be needed later, and desperately, the decision is yours, right now, many clinics aren't sure what they'll need or what they'll be able to get hold of if cases continue at the current predicted rates.

Other groups working on similar items

We are looking for design and maufacture locally to Nottingham, UK. Thee are lots of other people working on similar ideas. They are linked here for info: