Difference between revisions of "Sagar Chisel Mortiser"

(→Layout) |

|||

| Line 65: | Line 65: | ||

# On each piece to be mortised, determine a "reference face" and mark it lightly in pencil. | # On each piece to be mortised, determine a "reference face" and mark it lightly in pencil. | ||

# Prepare a "rod" | # Prepare a "rod" | ||

| − | + | ## Take a piece of scrap timber, ply or MDF, with at least one straight edge, and cut one end perpendicular to the straight edge. | |

| − | + | ## Using a sharp, dark pencil and a steel rule or combination square, make marks at the following distances: reference face to near side of mortise, reference face to far side of mortise, end of timber to beginning of mortise, end of timber to end of mortise and (if required) end of timber to end of haunch. | |

# Use the rod to make marks on each piece indicating the distances. | # Use the rod to make marks on each piece indicating the distances. | ||

# Using a Set-Square or Combination Square join these marks to form a rectangle indicating material to be removed. | # Using a Set-Square or Combination Square join these marks to form a rectangle indicating material to be removed. | ||

Revision as of 23:00, 27 August 2016

Purchased by a pledge drive, and currently being installed in the workshop.

About the Machine

Manufactured by J. Sagar & Co. Halifax, based on promotional materials it appears to be based on a design already in production by 1909, and subsequently re-designed in the late 20's to run on electrical rather than overhead belt power, living history right here in the hackspace no less.

What does it do?

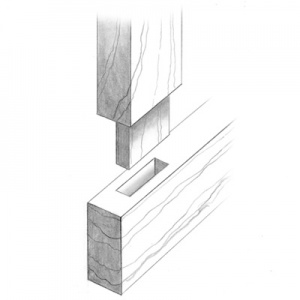

Put simply, it is a drill for square holes.

More comprehensively, A hollow chisel mortiser has a auger bit running inside a hollow, square chisel. Pulling the lever down brings the auger into the wood, cutting away the bulk of the material, before the chisel follows 1/16" behind, taking away the material in the corners to give a square hole.

Why do we want to do that?

Mortise and Tenon joints in all their many forms, remain the strongest and most secure method of joining two pieces of wood.

Cutting a tight-fitting hole, in a piece of wood, which is dead square in all three dimensions, using nothing more than a mallet and chisel, requires a substantial amount of skill and practice;[1] not to mention a reasonable amount of effort; by contrast a chisel mortiser allows all this to be done with little more than a push of a button, turn of a wheel and pull of a lever.[2]

It's hoped that this will open up some more ambitious and structural woodworking projects to all comers.[3]

Installation Progress

The machine is now in position, but inoperative until the power is connected.

The bolt which secures the chisel in position, unfortunately seized and subsequently sheered on attempting to free it. The remainder of the bolt has been drilled out, the residue of the threads removed with a tap, and a replacement (and spare) set-screw of the appropriate size (5/16 Whitworth) has been sourced.

Parts sourced:

- 2 × 5/16 BSW 2½" allen head set screws

Parts on order:

- 12m of 5 core, 2.5mm2 armoured cable.

- 20A rotary isolator.

- 440v DOL Motor Starter, with 1.8-2.5A thermal overload.

Parts to order:

- ½ or ¾ ply - 2'6" by 8" — sacrificial table top.

- New tooling.

Costs:

| Item | Qty. | Price per each | Total cost | Running total |

|---|---|---|---|---|

| # Morticer | 1 | £80.00 | £80.00 | £80.00 |

| Van Hire | 1 | £95.00 | £95.00 | £175.00 |

| Fuel | 1 | £20.03 | £20.03 | £195.03 |

| BSW Bolts | 2 | £1.50 | £3.00 | £198.03 |

| 3 Ph Cable | 12m | £2.78 | £33.36 | £231.39 |

| Isolator | 1 | £11.50 | £11.50 | £242.89 |

| DOL Starter | 1 | £35.49 | £35.49 | £278.38 |

Standard Operating Procedure

First select dimensions and layout of the joints, appropriate to the timbers to be joined.

Layout

- On each piece to be mortised, determine a "reference face" and mark it lightly in pencil.

- Prepare a "rod"

- Take a piece of scrap timber, ply or MDF, with at least one straight edge, and cut one end perpendicular to the straight edge.

- Using a sharp, dark pencil and a steel rule or combination square, make marks at the following distances: reference face to near side of mortise, reference face to far side of mortise, end of timber to beginning of mortise, end of timber to end of mortise and (if required) end of timber to end of haunch.

- Use the rod to make marks on each piece indicating the distances.

- Using a Set-Square or Combination Square join these marks to form a rectangle indicating material to be removed.

- Cross hatch the area to be removed

Setup

Machining

Tool Change Procedure

Wiring Diagram

Footnotes

- Indeed, it is not enough to develop the skill once, regular practice is essential to continue making a good job of it.

- The keen eyed reader will note that in the above advertisment, Sagar suggest that being usable by "a lad" was one of the machine's selling points.

- Especially the author, who always enjoys mortising by hand to begin with, before getting part-way through and realising that He's ultimately rather lazy.