Wood lathe: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

mNo edit summary |

||

| (28 intermediate revisions by 7 users not shown) | |||

| Line 1: | Line 1: | ||

{{Tool | |||

|image=File:Tool Wood Lathe.jpg | |||

|manufacturer=Generic Chinese | |||

|model=Similar to Charnwood 813 | |||

|obtained=Member Donation{{clarify|reason=Was this tool acquired after this pledge drive: [[Wood Lathe Pledge]]?}} | |||

|obtaineddate= | |||

|location=Dusty Area | |||

|team=Woodworking | |||

|induction=No | |||

|defunct= | |||

|defunctdate= | |||

}} | |||

'''Do not use this machines with materials that will generate silica dust. eg soapstone and other soft stones, sandstone, ceramics, gemstones''' | |||

A good reference on this subject https://ehs.princeton.edu/health-safety-the-campus-community/art-theater-safety/art-safety/sculpture | |||

The current Wood Lathe is a Chinese model - the [https://www.charnwood.net/products/product/floorstanding-lathe-w813/category_pathway-2 Charnwood 813] is a close match in terms of Specification. | |||

The lathe | The lathe has a mechanical speed control using a belt with variable diameter pulleys. It has a high maximum speed. | ||

The | ==Tips== | ||

The speed control must be set to a '''Low Speed before switch on'''. Once you've completed turning your part, the speed must be returned to a low speed before switching off. | |||

Make sure that the chuck is tightened with tools before use. | |||

{{note|If chuck and work-piece is heavy reduce the speed slowly otherwise there is a danger of the chuck unscrewing itself due to the momentum.}} | |||

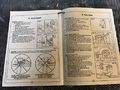

==Instruction Manual== | |||

<gallery perrow=3> | |||

Manual For Wood Lathe 1.jpg|Part 1 | |||

Manual For Wood Lathe 2.jpg|Part 2 | |||

Manual For Wood Lathe 3.jpg|Part 3 | |||

Manual For Wood Lathe 4.jpg|Part 4 | |||

Manual For Wood Lathe 5.jpg|Part 5 | |||

Manual For Wood Lathe 6.jpg|Part 6 | |||

Manual For Wood Lathe 7.jpg|Part 7 | |||

Manual For Wood Lathe 8.jpg|Part 8 | |||

Manual For Wood Lathe 9.jpg|Part 9 | |||

</gallery> | |||

==Resources== | |||

* [http://www.startwoodworking.com/plans/how-turn-basic-bowl How to Turn a Basic Bowl (Start Woodworking)] | |||

[[Category:Woodwork]] | |||

[[Category:Tools and Equipment]] | |||

Latest revision as of 14:01, 4 September 2022

| Wood lathe | |

|---|---|

| |

| Manufacturer | Generic Chinese |

| Model | Similar to Charnwood 813 |

| Obtained | Member Donation[clarify] |

| Location | Dusty Area |

| Team | Woodworking |

| Induction Required | No |

| Tools: all pages • list • Power Tools • Broken tools {{}} | |

Do not use this machines with materials that will generate silica dust. eg soapstone and other soft stones, sandstone, ceramics, gemstones

A good reference on this subject https://ehs.princeton.edu/health-safety-the-campus-community/art-theater-safety/art-safety/sculpture

The current Wood Lathe is a Chinese model - the Charnwood 813 is a close match in terms of Specification.

The lathe has a mechanical speed control using a belt with variable diameter pulleys. It has a high maximum speed.

Tips

The speed control must be set to a Low Speed before switch on. Once you've completed turning your part, the speed must be returned to a low speed before switching off.

Make sure that the chuck is tightened with tools before use.

Instruction Manual

-

Part 1

-

Part 2

-

Part 3

-

Part 4

-

Part 5

-

Part 6

-

Part 7

-

Part 8

-

Part 9