Laser cutter/LaserCut/Usage: Difference between revisions

→Importing Files: +unite lines |

|||

| (7 intermediate revisions by 3 users not shown) | |||

| Line 20: | Line 20: | ||

These line file formats can be imported: | These line file formats can be imported: | ||

* '''DXF - AutoCAD''' - this is our preferred method of import | * '''DXF - AutoCAD''' - this is our preferred method of import, with [[Laser cutter/Inkscape|Inkscape support]] (although with a limited colour palette) | ||

* AI - Adobe Illustrator File - need to know what is imported | * AI - Adobe Illustrator File - ''need to know what is imported'' | ||

* PLT - HPGL Plotter File - need to know what is imported, where this can be created from | * PLT - HPGL Plotter File - ''need to know what is imported, where this can be created from'' | ||

* TST - Tajima - need to know what is imported, where this can be created from | * TST - Tajima - ''need to know what is imported, where this can be created from'' | ||

* NC - Mastercam - need to know what is imported, where this can be created from | * NC - Mastercam - ''need to know what is imported, where this can be created from'' | ||

You can also import previously made ECP files by typing '''*.epc''' in the '''File Name:''' box and selecting '''Open''' - this will only import the lines and colours not the power settings or order, but is a reasonable way to save time if you wish to just get a completed design ready but don't have the original DXF or SVG. | You can also import previously made ECP files by typing '''*.epc''' in the '''File Name:''' box and selecting '''Open''' - this will only import the lines and colours not the power settings or order, but is a reasonable way to save time if you wish to just get a completed design ready but don't have the original DXF or SVG. | ||

| Line 30: | Line 30: | ||

[[File:LaserCut-Import-ECP.PNG|thumbnail|none|Importing ECP files into LaserCut]] | [[File:LaserCut-Import-ECP.PNG|thumbnail|none|Importing ECP files into LaserCut]] | ||

These image file formats can be imported: | These image file formats can be imported for engraving work: | ||

* BMP, JPG/JPEG, GIF, PNG, TIF/TIFF, TGA, PCX | * BMP, JPG/JPEG, GIF, PNG, TIF/TIFF, TGA, PCX | ||

If the program continually crashes importing, first of all entirely restart the program, and possibly de-select "Preview" so it doesn't read the file (it can fail if the file is open by something else). Otherwise INI file has become corrupt (perhaps on a crash of the program). Copying the original again by running the bat file fixes this. | If the program continually crashes importing, first of all entirely restart the program, and possibly de-select "Preview" so it doesn't read the file (it can fail if the file is open by something else). Otherwise INI file has become corrupt (perhaps on a crash of the program). Copying the original again by running the bat file fixes this. | ||

== Unite Lines == | |||

Make sure you use Unite Lines under the Tools menu to join up all the pieces of an imported file. The tolerance value is the distance between separated pieces - 0.01 is a fine value for this. Click Ok and the pieces are joined up to make the laser cut both more efficient and much more rigorous in keeping your design correct. | |||

== Saving files == | == Saving files == | ||

Saving in the demo: | Saving in the demo: | ||

* Can save ECP files on exit or if selecting "New" from File menu. Press '''Yes''' on the dialogue box to | * Can save ECP files on exit or if selecting "New" from File menu. Press '''Yes''' on the dialogue box to save as ECP, which exports up to 3 files; the '''.ECP''' which is similar to an SVG of the object with colours, the '''.INI''' contains the cut information and the '''.G00''' contains the engraving information. | ||

* Unite Lines are saved if ECP is imported again, but the laser cut/engrave/etc. settings for speed and power are lost | * Unite Lines are saved if ECP is imported again, but the laser cut/engrave/etc. settings for speed and power are lost | ||

** This however | ** This however can be better then just leaving it as a DXF since it does save all the united lines, positioning, tessellation, colours etc. | ||

* .MOL exports are the best | |||

Exporting the final thing to load: | |||

* '''.MOL''' exports are the best final file but any adjustments means re-creating them - they can be rather large files even for simple designs! You can do this using the Download button on the far right of the program, and selecting '''Export file'''. | |||

** These can also be put on the root of a USB stick to be copied using the USB port on the side, they get copied instantly with a message on the screen to display it. | |||

== Exporting MOL files == | == Exporting MOL files == | ||

'''NOTE:''' Both the demo and normal program can export .MOL as long as you have '''not''' used the tool ''Data Check'' (under ''Tools -> Data Check'') since this causes it to crash. To fix this either re-apply the default config file settings, or remove the line '''CheckLayerCode=-1''' under '''[DataCheck]'''. | '''NOTE:''' Both the demo and normal program can export .MOL as long as you have '''not''' used the tool ''Data Check'' (under ''Tools -> Data Check'') since this causes it to crash. To fix this either re-apply the default config file settings, or remove the line '''CheckLayerCode=-1''' under '''[DataCheck]''' in the "syscfg.ini" file. | ||

It is very likely that there are other tools which can cause the export to break, this is just the first one we discovered and reverting to the default configuration as mentioned above typically fixes it. If you encounter any other tools or options which cause the export to break please document it here. | |||

== Tiling / Multiplying objects == | == Tiling / Multiplying objects == | ||

| Line 52: | Line 61: | ||

== Colours == | == Colours == | ||

When importing a DXF file the main primary colours are retained. See the [[Laser cutter/Inkscape|Inkscape]] page for how to setup the correct palette for exporting valid colours to DXF. There are more advanced options available and other formats may retain further colour. For simple jobs you can also recolour the objects in LaserCut itself. | |||

You can use multiple colours in a design to separate different types of action; for instance a good practice may be to have: | You can use multiple colours in a design to separate different types of action; for instance a good practice may be to have: | ||

| Line 57: | Line 68: | ||

* Black - All cut lines | * Black - All cut lines | ||

* Blue - engrave areas | * Blue - engrave areas | ||

* Green - engrave | * Green - engrave-cut lines (cut option at a lower power). | ||

* Red and other colours - other engrave areas/lines | * Red and other colours - other engrave areas/lines | ||

If this method is used it can be easy to import a DXF file which has the correct layers already set up. | If this method is used it can be easy to import a DXF file which has the correct layers already set up. For instance: | ||

<gallery> | |||

File:LaserCut-Colours-Inkscape.PNG|Inkscape - black cut on edge, blue engrave areas, green engrave-cut lines | |||

File:LaserCut-Colours-Imported.PNG|Imported successfully into LaserCut with colours retained | |||

File:LaserCut-Colours-Imported-Preview.PNG|Preview of work to be done | |||

</gallery> | |||

== Machine Settings == | == Machine Settings == | ||

Simply put: please don't change any settings under ''File -> Machine-Options'' since the given settings are for the A0 laser we have, and incorrect settings can break the laser. | Simply put: please don't change any settings under ''File -> Machine-Options'' since the given settings are for the A0 laser we have, and incorrect settings can break the laser. | ||

There is a desktop shortcut to reset the LaserCut options. | |||

== Types of Cut == | == Types of Cut == | ||

| Line 109: | Line 122: | ||

* '''Speed''' - Speed in millimetres the laser moves at. For cuts this is usually 50 or lower, for engraves 300 and higher. The maximum is 400 speed since cuts can go both on the X and Y axis at once. | * '''Speed''' - Speed in millimetres the laser moves at. For cuts this is usually 50 or lower, for engraves 300 and higher. The maximum is 400 speed since cuts can go both on the X and Y axis at once. | ||

* '''Power''' - Percentage power of laser. Do not use higher than 65%, this is unnecessary and will burn the laser out or potentially burn your material. For cuts 65 and altering the speed is usually best, and for engraves a power of 30-40 seems to be better. | * '''Power''' - Percentage power of laser. Do not use higher than 65%, this is unnecessary and will burn the laser out or potentially burn your material. For cuts 65 and altering the speed is usually best, and for engraves a power of 30-40 seems to be better. | ||

* '''Corner power''' - It defaults to 15% but can be set to the used power, -10% or so (for 65% you could use 55% for instance). This is so it won't burn the corners since when the motors make it turn it will hold the laser in position for a little longer. | * '''Corner power''' - It defaults to 15% but can be set to the used power, -10% or so (for 65% you could use 55% for instance). This is so it won't burn the corners since when the motors make it turn it will hold the laser in position for a little longer. '''This notably can cause a good laser file to look odd, make sure it is set in tandem with the Power setting!''' | ||

* '''Overlap''' - The manual states a badly calibrated laser can use this to cut better; for ours this is unnecessary. Leave it alone. | * '''Overlap''' - The manual states a badly calibrated laser can use this to cut better; for ours this is unnecessary. Leave it alone. | ||

* '''...''' - Advanced options, leave them alone, the defaults are fine. | * '''...''' - Advanced options, leave them alone, the defaults are fine. | ||

| Line 189: | Line 202: | ||

'''This option is only in the Demo and does not appear in the final application. It crashes the Demo. Probably an oversight by the LaserCut developers. Do not select it!''' | '''This option is only in the Demo and does not appear in the final application. It crashes the Demo. Probably an oversight by the LaserCut developers. Do not select it!''' | ||

== Download == | |||

The DownLoad button will connect to the laser cutter to change what file is loaded (or in the demo allow exporting of .MOL files). | |||

It will when successfully connected display what files are already on the laser. | |||

Main things to note: | |||

* You can upload the LaserCut CFG as a first step to make sure there are no odd settings from the last user. This also means you can change some of the config settings and upload them to have the laser then use them (but be careful, it is not recommended). | |||

* Always delete all items before adding a new one - there is a size limit, and more than one large item can corrupt. | |||

* There is an easy way to upload fully configured .MOL files using the "Download File" option, select the MOL and it is uploaded. | |||

[[Category:Laser Cutter]] | [[Category:Laser Cutter]] | ||

Latest revision as of 23:00, 3 November 2014

This page will detail how to get the best out of LaserCut.

What is a cut versus and engrave?

The only difference of the two is that an engrave covers a bounded area with lots of small cuts. This means you can "engrave" lines into something using just cuts of a lower power.

Quirky Notes

NOTE: The demo software will crash in the demo on A0 "Silvertail" settings. Please change the file "syscfg - Silvertail.ini", find "NeedRevise=1" under section "[TWOAXIS_0]" and change it to "NeedRevise=0" - a revised download may be provided soon.

The software has some oddities - there are things hidden behind scroll bars and please note: the enter key never saves settings (in many cases) so you must click "Ok" to save things.

Also at the moment the word "Download" really should be "Upload".

The long-running tools (such as "Preview" and "Calculate time") have no cancel button but pressing escape seems to exit them fine.

Importing Files

LaserCut does not import direct SVG files; it requires more simple files to import. It can also work with images directly using them to direct engrave areas.

These line file formats can be imported:

- DXF - AutoCAD - this is our preferred method of import, with Inkscape support (although with a limited colour palette)

- AI - Adobe Illustrator File - need to know what is imported

- PLT - HPGL Plotter File - need to know what is imported, where this can be created from

- TST - Tajima - need to know what is imported, where this can be created from

- NC - Mastercam - need to know what is imported, where this can be created from

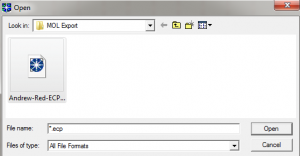

You can also import previously made ECP files by typing *.epc in the File Name: box and selecting Open - this will only import the lines and colours not the power settings or order, but is a reasonable way to save time if you wish to just get a completed design ready but don't have the original DXF or SVG.

These image file formats can be imported for engraving work:

- BMP, JPG/JPEG, GIF, PNG, TIF/TIFF, TGA, PCX

If the program continually crashes importing, first of all entirely restart the program, and possibly de-select "Preview" so it doesn't read the file (it can fail if the file is open by something else). Otherwise INI file has become corrupt (perhaps on a crash of the program). Copying the original again by running the bat file fixes this.

Unite Lines

Make sure you use Unite Lines under the Tools menu to join up all the pieces of an imported file. The tolerance value is the distance between separated pieces - 0.01 is a fine value for this. Click Ok and the pieces are joined up to make the laser cut both more efficient and much more rigorous in keeping your design correct.

Saving files

Saving in the demo:

- Can save ECP files on exit or if selecting "New" from File menu. Press Yes on the dialogue box to save as ECP, which exports up to 3 files; the .ECP which is similar to an SVG of the object with colours, the .INI contains the cut information and the .G00 contains the engraving information.

- Unite Lines are saved if ECP is imported again, but the laser cut/engrave/etc. settings for speed and power are lost

- This however can be better then just leaving it as a DXF since it does save all the united lines, positioning, tessellation, colours etc.

Exporting the final thing to load:

- .MOL exports are the best final file but any adjustments means re-creating them - they can be rather large files even for simple designs! You can do this using the Download button on the far right of the program, and selecting Export file.

- These can also be put on the root of a USB stick to be copied using the USB port on the side, they get copied instantly with a message on the screen to display it.

Exporting MOL files

NOTE: Both the demo and normal program can export .MOL as long as you have not used the tool Data Check (under Tools -> Data Check) since this causes it to crash. To fix this either re-apply the default config file settings, or remove the line CheckLayerCode=-1 under [DataCheck] in the "syscfg.ini" file.

It is very likely that there are other tools which can cause the export to break, this is just the first one we discovered and reverting to the default configuration as mentioned above typically fixes it. If you encounter any other tools or options which cause the export to break please document it here.

Tiling / Multiplying objects

Select the option Set array output options from the toolbar. This will help create copies of an object which can be altered so they overlap nicely. It isn't a perfect way to tessellate an object (using one cut line for two objects for instance) but is good enough for non-tessellating objects to be multiplied for multiple copies quickly, and is a lot easier than using Inkscape to do the same thing.

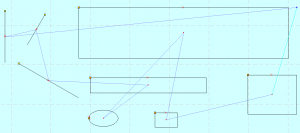

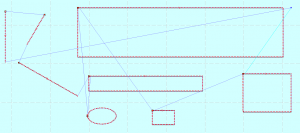

Colours

When importing a DXF file the main primary colours are retained. See the Inkscape page for how to setup the correct palette for exporting valid colours to DXF. There are more advanced options available and other formats may retain further colour. For simple jobs you can also recolour the objects in LaserCut itself.

You can use multiple colours in a design to separate different types of action; for instance a good practice may be to have:

- Black - All cut lines

- Blue - engrave areas

- Green - engrave-cut lines (cut option at a lower power).

- Red and other colours - other engrave areas/lines

If this method is used it can be easy to import a DXF file which has the correct layers already set up. For instance:

-

Inkscape - black cut on edge, blue engrave areas, green engrave-cut lines

-

Imported successfully into LaserCut with colours retained

-

Preview of work to be done

Machine Settings

Simply put: please don't change any settings under File -> Machine-Options since the given settings are for the A0 laser we have, and incorrect settings can break the laser.

There is a desktop shortcut to reset the LaserCut options.

Types of Cut

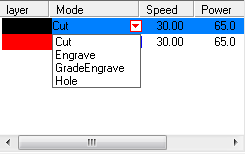

You can set different coloured items to do different things - such as having one set of cut lines cut though, while another set of cut lines only engraves at a lower power. These are the dropdown options on the layer selector:

Basic Settings

These are some recommended numbers to take into account:

Remember: Power and Speed affect the cuts/engraves equally; a slower cut of 30mm will cut through 3mm wood at 65% power, while 600mm at 65% power will only engrave the wood partially. Equally a higher power at the same speed will cut deeper.

Power:

- The laser cutter power is in percent.

- Usually you want to maximise the power used, so the speed can be increased to make the cut time shorter.

- Please limit upper power to 65%, especially since higher can make things burn.

- The lowest appreciable power appears to be around 12%, at slow speeds it can just about etch lightly some wood, but might be more applicable to paper cutting.

Speed:

- Speed affects the accuracy of cuts as well as the time they take - tiny 400mm cuts may be wonky for instance. Try lowering it to 300 or 200mm instead at a lower power to achieve the same effect.

- Engraving cuts can be as high as 1000mm, which is fine due to it being only on one axis of movement. It requires high power however to make any effect at this speed and may result in some bad engraving.

Overlapping areas

- Each line / area is done once, regardless of if it overlaps something else. The order of the colours may be important - cutting last is usually the best method to get a clean finish since if you cut first the item may drop/move when released from the surrounding material.

- The fact you can overlap areas of engrave or lines of cut means you can achieve multi-later engraves and cuts.

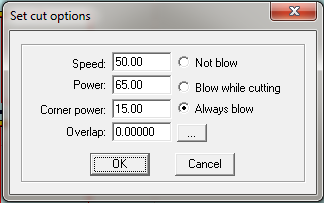

Cut

A cut is a single run of the laser at a set power along a desired line. This line can be at any angle, or in circular patterns.

This means you can either cut through a material or leave a thin engrave line the exact width of the laser; around 0.1mm size.

- Speed - Speed in millimetres the laser moves at. For cuts this is usually 50 or lower, for engraves 300 and higher. The maximum is 400 speed since cuts can go both on the X and Y axis at once.

- Power - Percentage power of laser. Do not use higher than 65%, this is unnecessary and will burn the laser out or potentially burn your material. For cuts 65 and altering the speed is usually best, and for engraves a power of 30-40 seems to be better.

- Corner power - It defaults to 15% but can be set to the used power, -10% or so (for 65% you could use 55% for instance). This is so it won't burn the corners since when the motors make it turn it will hold the laser in position for a little longer. This notably can cause a good laser file to look odd, make sure it is set in tandem with the Power setting!

- Overlap - The manual states a badly calibrated laser can use this to cut better; for ours this is unnecessary. Leave it alone.

- ... - Advanced options, leave them alone, the defaults are fine.

Examples: to follow.

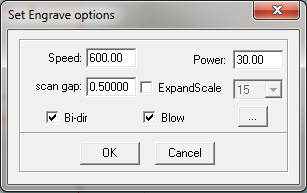

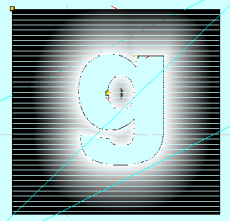

Engrave

Engraving means the laser is moved over an area with a lower power or faster speed to allow the surface to be engraved with a pattern. There are further options to decide the gap between the scan lines which cover the area.

Note that any line you select for engrave which doesn't contain a contiguous area will still be engraved, just it will overlap with where the line is. Check the preview for how this looks.

- Speed - Speed in millimetres the laser moves at. Engraves can vary at speed, but 300 or higher is highly recommended (600 - 800 can work well). The maximum for engraves is a high 1000, which is because it is only going on the X axis means the upper limit is higher.

- Power - Percentage power of laser. Do not use higher than 65%, this is unnecessary and will burn the laser out or potentially burn your material. For cuts 65 and altering the speed is usually best, and for engraves a power of 30-40 seems to be better.

- Scan gap - The distance in millimeters between each line on this engrave area. This setting will vary by material - it can go very low. The laser should be around 0.1mm for the single point it fires, but make sure you experiment! Some reasonable defaults may be:

- 100DPI - 0.25

- 250DPI - 0.1

- 300DPI - 0.085

- ExpandScale - This will overscans or underscans the area that the shape is. This can be very useful to allow for the kind of thick lines something might be drawn in InkScape which you might not account for when it is imported into LaserCut. It will also helpfully affect single lines you've selected for engraving.

- Bi-dir - Does the laser do both left and right engraves? If unticked it will only do one direction (and be slower) but might be better for certain materials.

- Blow - Controls the air flow, always leave enabled.

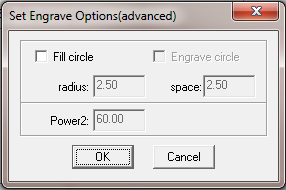

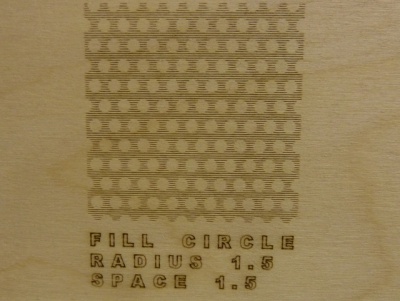

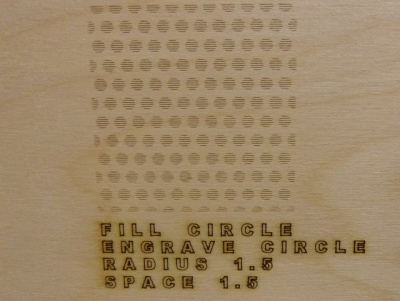

- ... - Advanced Engrave options:

- Fill circle - Will allow the other options to be selected.

- Engrave circle - If off, it will engrave and leave circles un-engraved. If on, it will engrave just circles. Potentially this can be used to cut but is inefficient, possibly good for marking areas without engraving them entirely.

- Radius - Radius of the circle in MM

- Space - Space between circles in MM

- Power2 - Ignore, we don't have a second laser on our laser cutter, so it is diasbled.

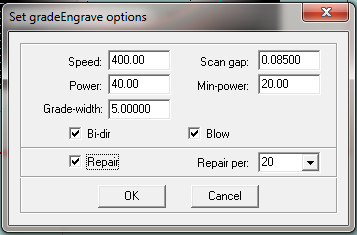

Grade Engrave

Grade Engrave will cause an area inside a engraved area to have raised edges. It is intended for easier rubber stamp making but can be applied to any real use. It is easiest to show with pictures:

There are options for this similar to Engrave:

- Speed - Speed in mm of the engrave. Set to whatever speed at the deepest should be.

- Scan gap - The gap on the Y axis between scan lines. 0.08500 is similar to 300DPI. The laser cuts roughly slightly less then 1mm holes.

- Power - The baseline maximum power, used for areas not near text (black in the above example)

- Min-power - The minimum power, used nearest to the edge of the lettering, where it is whitest.

- Bi-dir - Should remain on usually, if turned off it will only cut on one direction pass of the laser, slowing it down.

- Blow - Should remain on, blows the air onto the area.

- Repair - A vague option; not tested fully. The manual states "select this option and the engraved letters will be clearer".

- Repair per - A vague option of a vague option; not tested fully. Defaults to 20. The manual states helpfully "change the parameter will adjust the definition of the engraved letters". Higher? lower? You guess!

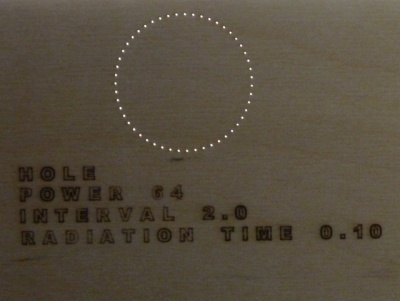

Hole

This may be useful for marking small areas or centres of objects and has two main options:

Hole on center

This puts a single laser cut at a specific power in the middle of all the selected objects. This could be useful for marking where things will end up, or for shapes like circles having the center marked (maybe after cutting and engraving it initially) for where attachments go. The output looks like this:

Holes on the lines

When Hole on center is not ticked, it will allow you to have single laser holes cut at intervals. This may be useful to put perforations in paper or card (although they may not work very well!) or for marking areas or having a different style of line engrave at lower powers. The output looks like this:

Note: Setting the interval too low (eg: 0.1) will essentially result in a cut which is made up of lots of holes and will result in a bad finish around the edges.

Pen Cut

This option is only in the Demo and does not appear in the final application. It crashes the Demo. Probably an oversight by the LaserCut developers. Do not select it!

Download

The DownLoad button will connect to the laser cutter to change what file is loaded (or in the demo allow exporting of .MOL files).

It will when successfully connected display what files are already on the laser.

Main things to note:

- You can upload the LaserCut CFG as a first step to make sure there are no odd settings from the last user. This also means you can change some of the config settings and upload them to have the laser then use them (but be careful, it is not recommended).

- Always delete all items before adding a new one - there is a size limit, and more than one large item can corrupt.

- There is an easy way to upload fully configured .MOL files using the "Download File" option, select the MOL and it is uploaded.