TIG welder: Difference between revisions

No edit summary |

hack notice |

||

| Line 1: | Line 1: | ||

{{Hacknotice|inductionsafely}} | |||

{{Tool | {{Tool | ||

|image=File:TIGWelderMiller Dialarc.jpg | |image=File:TIGWelderMiller Dialarc.jpg | ||

| Line 16: | Line 17: | ||

The TIG welder is a 'stick' welder - the electrode / nozzle is held in one hand, and the filler wire applied with the other. | The TIG welder is a 'stick' welder - the electrode / nozzle is held in one hand, and the filler wire applied with the other. | ||

==Shield gas == | ==Shield gas == | ||

For the TIG we use a [http://www.boconline.co.uk/en/products-and-supply/industrial-gases/inert-gases/pureshield-argon/pureshield-argon.html Pureshield Argon].<br/> | For the TIG we use a [http://www.boconline.co.uk/en/products-and-supply/industrial-gases/inert-gases/pureshield-argon/pureshield-argon.html Pureshield Argon].<br/> | ||

Revision as of 14:08, 24 February 2019

| This tool requires induction to use safely. Please request via HMS. |

| TIG welder | |

|---|---|

| |

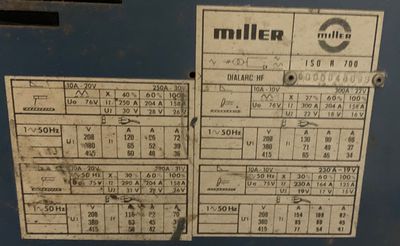

| Manufacturer | Miller |

| Model | Dialarc HF |

| Location | Metalworking Area |

| Team | Metalworking |

| Induction Required | Yes (use request form) |

| Tools: all pages • list • Power Tools • Broken tools {{}} | |

TIG (Tungsten Inert Gas) welding is particularly useful for aluminium, It uses an electrode nozzle with a fixed (should be permanent, but they do wear) tungsten tip where a plasma 'flame' is created (started with a high-voltage / high freequency starter) and used to heat the filler wire and joint. The nozzle allows a flow of inert shield gas around the working area, reducing slag creation and (particularly important with aluminium) oxidation.

The TIG welder is a 'stick' welder - the electrode / nozzle is held in one hand, and the filler wire applied with the other.

Shield gas

For the TIG we use a Pureshield Argon.

Gas bottle replacement log

| Date | Who | Notes |

|---|---|---|

| 06/06/15 | Matt | First Bottle |

| 11/06/15 | Russell |

Capacity and rating

The Tig welder has a large range

Power is from a 63 amp socket, on the highest setting the Tig could draw more current than this

Controls

Details on the front panel controls

Tungsten and collets

We have a selection of the following tungsten tips and collets to fit

| Size | Color band | Grade | Used for | Notes |

|---|---|---|---|---|

| 1.6mm | Red | 2% Thoriated | DCEN Steel | Slightly radioactive! Do not sharpen without wearing a dust mask. |

| 2.4mm | Red | 2% Thoriated | DCEN Steel | Slightly radioactive! Do not sharpen without wearing a dust mask. |

| 1.6mm | White | Zirconaited | AC Aluminium | |

| 2.4mm | White | Zirconaited | AC Aluminium | |

| 1.6mm | Gold | 1.5% Lanthanated | AC or DCEN, All rounder Steel or Aluminium | |

| 2.4mm | Gold | 1.5% Lanthanated | AC or DCEN, All rounded Steel or Aluminium |

Tungsten electrodes come in a a range of different grades/types, each performs differently and have their own uses.

They are marked with a colour band at one end, do not grind this off!

The following was borrowed from here

ZIRCONIATED Tungsten Color Code WHITE or BROWN, are best suited for AC Tig welding applications.

Zirconiated, White, AC Welding applications. Better start up than Pure Tungsten, Balls up well and has a more stable arc than Pure Tungsten. Better current carrying capacity and high resistance to contamination during welding.

LANTHANATED Tungsten Color Code BLACK, GOLD or BLUE, is suitable for AC & DC welding applications.

Lanthanated, Black, AWS Class EWLA-1.5, AC & DC welding applications. Non-Radioactive Good arc characteristics in ac/dc applications. Applications: carbon & stainless steel, nickel alloys and titanium.

CERIATED Tungsten Color Code GREY or ORANGE, are best suited for low amperage DC welding applications.

Ceriated, Grey, An excellent alternative to Thoriated tungsten especially in low amperage welding. Takes 10% less current to start and has a very stable arc.

PURE Tungsten Color Coded GREEN, are best suited for AC Tig welding applications.

Pure Tungsten, Green, AWS Class EWP, AC welding applications. Least expensive of all electrodes. Applications: aluminum and magnesium alloys.

THORIATED Tungsten Color Code RED, YELLOW, MAUVE or ORANGE, is best suited for DC Tig welding applications.

2% Thoriated, Red, AWS Class EWTH-2, DC welding applications. The most common type of electrode used today. Applications: carbon & stainless steel, nickel alloys and titanium.

Grinding tip shapes

Do not grind the end with the color band!

Filler rods

We have the following stock of filler rods

- Steel

- Stainless steel

- Aluminium

- Copper

Power supply

A 63A plug and socket connection is used, with a pushbutton on/off control station and no-volt release.

RFID control of access will be installed shortly.

Tig welding tips

Random collection of useful links