BarBot/Components/Cherry Conveyor: Difference between revisions

Iandickinson (talk | contribs) No edit summary |

Iandickinson (talk | contribs) |

||

| Line 19: | Line 19: | ||

The cycle length is unfortunately not fixed. It just depends on how long the next cherry takes to move along the belt and whether it needs a push from those behind it. A time-out may need to be added to reduce the risk of dropping a cherry after the glass has moved on. | The cycle length is unfortunately not fixed. It just depends on how long the next cherry takes to move along the belt and whether it needs a push from those behind it. A time-out may need to be added to reduce the risk of dropping a cherry after the glass has moved on. | ||

===Connections=== | ===Connections (conveyor) === | ||

{| class="wikitable" | |||

|- | |||

! 9 way D pin no!! Signal | |||

|- | |||

| 1 || N/C | |||

|- | |||

| 2 || Stepper coil A | |||

|- | |||

| 3 || Stepper coil A | |||

|- | |||

| 4 || Stepper coil B | |||

|- | |||

| 5 || Stepper coil B | |||

|- | |||

| 6 || N/C | |||

|- | |||

| 7 || IR sensor | |||

|- | |||

| 8 || IR LED | |||

|- | |||

| 9 || Ground | |||

|} | |||

===Connections (L298N module)=== | |||

* +12V | * +12V | ||

* Ground | * Ground | ||

Revision as of 15:14, 12 July 2014

Cherry Conveyor

General Description

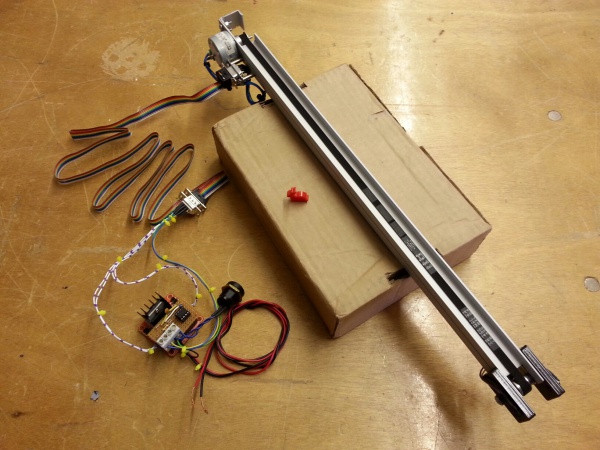

The cherry conveyor dispenses a single cherry (well, it does most of the time, but sometimes you get two!). It's made from a stepper motor and belt recycled from an old printer. The stepper is driven by a L298N dual H-bridge and is controlled by a ATtiny85. Once started the conveyor runs until the IR LED and receiver see a cherry dropping off the end of the belt. When a cherry does drop, the belt runs backward momentarily to prevent further cherries being close to the end. The belt has capacity for about 25 cherries. The mechanism could probably be used to dispense olives too, but to date this has not been tested.

Notes:

- Do not use glace cherries! They are too sticky and will cause the mechanism to cease.

- Spreewaldhoe Kaiserkirschen from Lidl work well! These are in a watery syrup.

- After use the mechanism should be run under a tap to clean it, however try to avoid getting the motor wet.

- The IR sensor does not work correctly in bright sunlight. It will dispense all the cherries in one go! (If operating in bright sunlight the IR sensor needs to be shielded.)

Mounting & hardware

The rail should be supported from below and the sides.

Logical

To dispense one cherry the /RESET line of the ATtiny85 needs to be taken low. The cycle length is unfortunately not fixed. It just depends on how long the next cherry takes to move along the belt and whether it needs a push from those behind it. A time-out may need to be added to reduce the risk of dropping a cherry after the glass has moved on.

Connections (conveyor)

| 9 way D pin no | Signal |

|---|---|

| 1 | N/C |

| 2 | Stepper coil A |

| 3 | Stepper coil A |

| 4 | Stepper coil B |

| 5 | Stepper coil B |

| 6 | N/C |

| 7 | IR sensor |

| 8 | IR LED |

| 9 | Ground |

Connections (L298N module)

- +12V

- Ground

- /RESET ("start" signal)

Power

+12V, TBC mA

Bling

None really! However, there is a red LED on the L298N module which illuminates when power is available. There is also a yellow LED on the ATtiny85 board which flashes rapidly whilst the belt is moving, then once the belt has stopped indicates the status of the IR sensor. This can be used to check the IR sensor is working.