Les Plywood: Difference between revisions

No edit summary |

|||

| Line 184: | Line 184: | ||

|} | |} | ||

===Fret Board=== | ===Gathering Materials=== | ||

====Fret Board==== | |||

I have ordered a piece of Indian Rosewood from Ebay. Price including postage £12.30. The piece is a little bit larger than I require so I will be testing it in the laser cutter when it arrives to see if I can engrave the inlays/ fret locations. | I have ordered a piece of Indian Rosewood from Ebay. Price including postage £12.30. The piece is a little bit larger than I require so I will be testing it in the laser cutter when it arrives to see if I can engrave the inlays/ fret locations. | ||

| Line 190: | Line 192: | ||

https://www.ebay.co.uk/itm/Guitar-Indian-Rosewood-Fretboard-luthier-Tonewood/123489924277 | https://www.ebay.co.uk/itm/Guitar-Indian-Rosewood-Fretboard-luthier-Tonewood/123489924277 | ||

===Fret Wire=== | ====Fret Wire==== | ||

I have ordered 1.8m of DHP-20 fret wire from eBay. | I have ordered 1.8m of DHP-20 fret wire from eBay. | ||

| Line 199: | Line 201: | ||

</Gallery> | </Gallery> | ||

===Truss Rod=== | ====Truss Rod==== | ||

In order to adjust the action of the neck, a truss rod is needed. Without looking into it too much I ordered this 480mm one from ebay: https://www.ebay.co.uk/itm/391966334841 | In order to adjust the action of the neck, a truss rod is needed. Without looking into it too much I ordered this 480mm one from ebay: https://www.ebay.co.uk/itm/391966334841 | ||

Cost just under £10. | Cost just under £10. | ||

Revision as of 01:10, 27 December 2018

| Les Plywood | |

|---|---|

| Created | 21/12/2018 |

| Members | danspencer101 |

| Status | In Progress |

Intro

Can a Les Paul guitar be produced through laser cutting? Probably, yes but anyone who knows anything about guitars would ask why... Well, I wanted to give this a go for no real reason other than its something to do that will challenge my skills. I am under no illusions that plywood is not an ideal material for an electric guitar but I'm going to try it anyway!

Making the Body

CAD

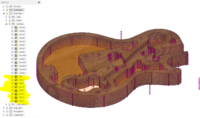

Model in Fusion 360

First things first I needed a model to create the DXF files for the laser cutter. I used a reference image that I found online and modelled it up in Fusion 360. See Here for the reference I used. I have deviated slightly from the plan as it is very badly drawn and doesn't follow any engineering standards at all. Anyway, it was good enough for me to put together a model :)

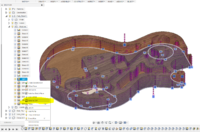

Once I had the model in Fusion 360 I produced a stack of planes that intersected the model and put a blank sketch on each of these planes. I then named all of the sketches to DXF Sketch 1 through to 8 as shown in the image. To pick up the geometry of the model you need to do an intersect in the sketch, its not automatic as I first thought. Then right click the sketch and save to DXF.

Arrange in Inkscape

With the DXF stack ready I then moved over to inkscape. Importing the sketches one at a time (Making sure to check that I was working in mm) and arranging them onto the 800mmx600mm page resulted in something that looks like this. These can then be taken over to Lasercut5.3 via any method you prefer.

Laser Cutting

I took a couple of videos and have uploaded them to youtube. See below.

Apologies about the vertical video, what was I thinking!

Gluing

Alignment

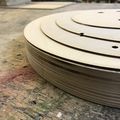

I put some through going 5mm holes into the model for aligning the stack. I used M5 machine bolts and am hoping to be able to unscrew them once the glue has dried. This alignment method has worked quite well but hasn't resulted in a perfectly smooth external surface. Oh well, the imperfections can be sanded away and any that remain will just add character. The very top layers were aligned using 10mm dowels in the holes where the bridge will go. Seemed to work ok!

Clamping Arrangement

-

Stage 1

-

Stage 2

Result

-

Electronics Pocket

-

Pickup Selector Pocket

-

Flat Top (Note this picture was taken before I glued on the curve top layers)

-

With the curve top on

-

Another with the curve top on

Sanding

I hadn't originally intended to sand this at all but the edges were just a bit too rough due to the misalignment between layers and it didn't feel nice to hold so my hand was forced. The top was sanded using the mouse/ palm sander in the dusty area. I wanted to maintain the layered look of the laser cut layers so didn't go over the top; just broke the sharp edges.

For the edges I used a combination of the disk sander and a drill mounted drum sander, both inside the dusty area. This worked well and has made the guitar nicer to hold whilst maintaining the characteristic layered effect of the ply.

-

Layers easily visible on the Edge but overall quite smooth

-

Top View

-

Back View

-

Curve Top

Building the neck

CAD

I have modelled the neck with a 5 degree angle from the body and a 15 degree head stock angle. Still need to model in the slot for the truss rod and frets. I'm waiting for the truss rod to arrive before I model it in so I can measure it and get the anchor points correct. I'd like to do the majority on the laser with ply and then glue an approx 5mm thick hardwood veneer on top for the fret board.

Fret Positions

The model I'm producing has a scale length of 625mm. That is the distance of the vibrating length of string, as the scale length affects the sound the guitar makes it is important to get the frets in position as accurately as possible. The numbers below were taken from the fret calculator here: https://www.stewmac.com/FretCalculator

| Fret | Distance from nut | Fret to Fret Distance |

|---|---|---|

| 1 | 35.079mm | 35.079mm (nut-1) |

| 2 | 68.188mm | 33.110mm (1-2) |

| 3 | 99.440mm | 31.251mm (2-3) |

| 4 | 128.937mm | 29.497mm (3-4) |

| 5 | 156.779mm | 27.842mm (4-5) |

| 6 | 183.058mm | 26.279mm (5-6) |

| 7 | 207.863mm | 24.804mm (6-7) |

| 8 | 231.275mm | 23.412mm (7-8) |

| 9 | 253.373mm | 22.098mm (8-9) |

| 10 | 274.231mm | 20.858mm (9-10) |

| 11 | 293.918mm | 19.687mm (10-11) |

| 12 | 312.500mm | 18.582mm (11-12) |

| 13 | 330.039mm | 17.539mm (12-13) |

| 14 | 346.594mm | 16.555mm (13-14) |

| 15 | 362.220mm | 15.626mm (14-15) |

| 16 | 376.969mm | 14.749mm (15-16) |

| 17 | 390.890mm | 13.921mm (16-17) |

| 18 | 404.029mm | 13.140mm (17-18) |

| 19 | 416.431mm | 12.402mm (18-19) |

| 20 | 428.137mm | 11.706mm (19-20) |

| 21 | 439.186mm | 11.049mm (20-21) |

| 22 | 449.615mm | 10.429mm (21-22) |

Gathering Materials

Fret Board

I have ordered a piece of Indian Rosewood from Ebay. Price including postage £12.30. The piece is a little bit larger than I require so I will be testing it in the laser cutter when it arrives to see if I can engrave the inlays/ fret locations.

https://www.ebay.co.uk/itm/Guitar-Indian-Rosewood-Fretboard-luthier-Tonewood/123489924277

Fret Wire

I have ordered 1.8m of DHP-20 fret wire from eBay. Cost including postage approx. £20

-

DHP-20 Wire

Truss Rod

In order to adjust the action of the neck, a truss rod is needed. Without looking into it too much I ordered this 480mm one from ebay: https://www.ebay.co.uk/itm/391966334841

Cost just under £10.