Laser Stamps: Difference between revisions

No edit summary |

No edit summary |

||

| Line 49: | Line 49: | ||

== Links == | == Links == | ||

*[http://www.epiloglaser.com/sc_stamps.htm Info from Epilog Laser] | *[http://www.epiloglaser.com/sc_stamps.htm Info from Epilog Laser] | ||

*[http://learn.adafruit.com/laser-custom-stamps AdaFruit Laser Stamp tutorial] | |||

[[Category:Projects]] | [[Category:Projects]] | ||

[[Category:Projects (complete)]] | [[Category:Projects (complete)]] | ||

[[Category:Featured]] | [[Category:Featured]] | ||

Revision as of 16:28, 8 March 2013

This is a guide to making rubber stamps on the laser cutter.

Stuff required

Firstly you will need some laser rubber, which can safely be cut on the laser cutter without loads of fumes. There are only a couple of suppliers that I have found (please add any, if you know) in the UK:

I had to buy this in bulk as shipping was quite expensive. Its around £7 a sheet, plus £6 p&p, plus VAT. If you would like a small bit to try then I am selling the excess from mine at £5 for an A6 piece (1/4 A4 - enough to make a load of stamps). Email matt_AT_re-innovation.co.uk.

Laser rubber is pretty boring and looks like this:

You will also need a rubber stamp ink pad and some structure to hold the stamp (a block of wood with a handle). I used this automatic inking rubber stamp as it was going up for grabs.

Make your stamp image

Make your image on your favourite graphics package. The image should be just black and white, as there is no graduated colour on a stamp. Make sure its the correct size. Remember:

- It needs to be printed white where you want the image and black where you want it cut away (generally invert the colour on the image)

- Also remember is to mirror the image, as it will be printed in reverse (I didn't do this on my first one).

Export it as a bitmap or jpeg.

Cut out the stamp with the laser cutter

We will be using the laser cutter as a laser engraver (actually thats what this laser machine is).

Import the image into the laser cutter program (The amazingly named 'Newly Draw' in Nottinghack case).

Test it out on a piece of wood - does it look OK?

To cut the rubber, the settings I used are: speed 50, power 200. This made a reasonable depth (around 1mm).I would suggest using even slower speed to make it even deeper. I will check next time with just 20 as the speed. Edit: Making the laser go slowly makes the rubber heat up and expand and causes distortion on the cut surface. After loads of attempts, I have found the best settings to be high power (400) and high speed (200) and then do two passes with the laser.

Cut the stamp out with a sharp knife. Any point edges might affect the stamp, so go pretty close to the raised surface. You can see in the next photo that I get a load of ink around the edges. I should either cut it off or stick it down onto a more rigid surface.

Glue the stamp onto some wood backing (with handle added). Prime with ink and stamp everything in sight.

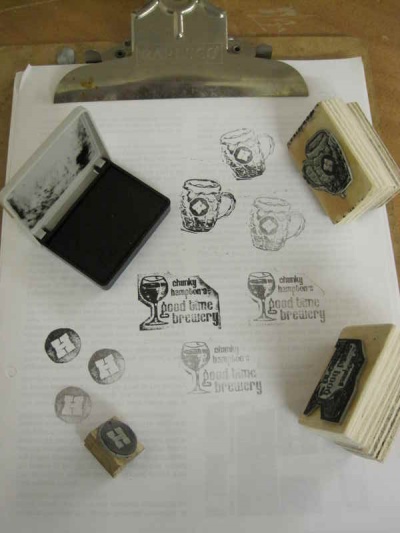

Some of the rubber stamps I have made recently: