Startrite Bandsaw

| Startrite Bandsaw | |

|---|---|

| |

| Manufacturer | Startrite |

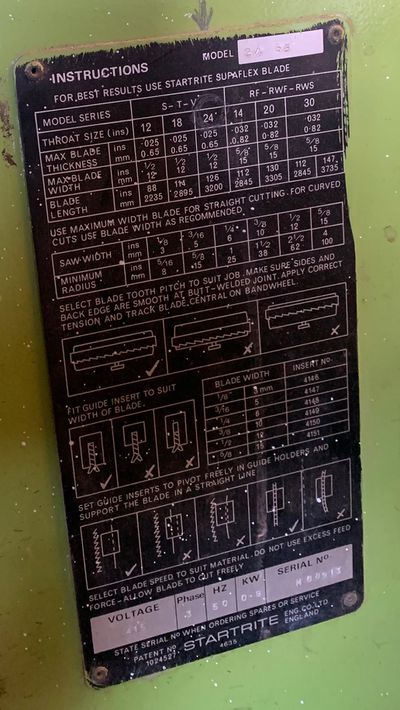

| Model | 24-S-5 |

| Obtained | Pledge Drive (June 2015) |

| Location | Metalworking_Downstairs |

| Team | Metalworking |

| Induction Required | No |

| Tools: all pages • list • Power Tools • Broken tools {{}} | |

Known as Willow.

History

See the back story on the Startrite metal bandsaw pledge page.

This tool was moved downstairs on the 06/12/2025 Hack the Space day to be eventually recommissioned when Metalworking moves downstairs.

Specification

3 (12") wheels, 5 speed, 24" throat bandsaw.

Cast-iron two-part tiltable table.

Powered from 415V three phase supply.

Usage

This tool is intended for cutting a range of non-ferrous and non-metallic materials (see the handbook); in the Hackspace, this is intended only for metal cutting, and the blade installed reflects this.

Ferrous (Iron, Steel, Stainless Steel) materials can only be cut provided that care is taken, and no excess pressure is applied.

The band speed should remain set to the slowest for maximum compatibility with a wide range of materials. The Hackspace is not a production workshop, and the higher speeds will only reduce the life of the blades.

Safety

Blades and Maintenance

Blade length is 3200mm / 126", 1/2" to 3/4" wide. These cost £19 - £25 each.

The first blade bought is a MK Morse M42 bimetal 1/2" x 10-14tpi varipitch from Bandsaw Blades Direct in Heanor. This is a general-purpose production-quality blade for cutting materials between 6mm and 35mm in thickness. A second, coarser, 3/4" x 6-10tpi varipitch blade has been bought for trial when the existing blade fails, which we're told should last longer (fewer teeth within the material being cut means that they don't overheat)

Blade Break-In: Extremely Important (from MK Morse blade materials)

The extremely sharp tooth points and edges of new blades must be broken-in before applying full feed pressure to the blade. A good analogy is that of writing with a freshly sharpened wooden pencil.

Recommended Break-In Procedure

- Maintain proper blade speed for the material to be cut.

- Reduce blade feed pressure or feed rate by 50% for the first 50 to 100 square inches of material cut.

- Gradually increase feed pressure or feed rate after break-in to target pressure or rate.

Further information concerning blade selection, MK Morse blade materials and troubleshooting. Possible sources of replacement parts: tyres and guides and tyres

A trial (May - June 2016) of lower cost HSS fixed-pitch blades showed no advantages in cost / lifetime, but showed that one real advantage of the vary-pitch blades is that they don't screech - which the fixed-pitch ones did.

Recommended Regular Maintenance

From the handbook

- Weekly

Remove embedded chips from the bandwheel tyres Clean upper and lower blade guide assemblies and check for wear

- Monthly

Check condition and tension of vee belts (motor drive cabinet)

- General

Clean and lubricate working parts as required. (The bandwheels have sealed-for-life bearings which do not require further lubrication. Check that the operating speed is set appropriately for the blade in use (to be determined and documented) and check availability of blades.