Superbox CNC Router: Difference between revisions

DauntlessA (talk | contribs) Major additions, particularly 'File Structure'. Simplified 'homing' section and some corrections (it is not possible to break the machine during homing). |

DauntlessA (talk | contribs) m Single typo correction |

||

| Line 281: | Line 281: | ||

G54 is a coordinate system that is offset from the machine coordinate system. I.e. when you set a position as zero in G54, the CNC is storing this zero position as offsets in X, Y, Z from the machine's origin. | G54 is a coordinate system that is offset from the machine coordinate system. I.e. when you set a position as zero in G54, the CNC is storing this zero position as offsets in X, Y, Z from the machine's origin. | ||

It is used to tell the CNC software where you have secured your workpiece to the table (Set Zero), so | It is used to tell the CNC software where you have secured your workpiece to the table (Set Zero), so it needs to be set before any program is run! The position of the G54 origin should match the origin in your CAM software. | ||

[[File:Tool gmoccapy - Probing.PNG|300px|right|thumbnail|Probing menu icon]] | [[File:Tool gmoccapy - Probing.PNG|300px|right|thumbnail|Probing menu icon]] | ||

Revision as of 03:18, 26 May 2023

| Superbox CNC Router | |

|---|---|

| |

| Manufacturer | Marchant Dice |

| Obtained | Acquired from Wireless Things after their close (2016) |

| Location | Laser Area |

| Team | Tools |

| Induction Required | No |

| Tools: all pages • list • Power Tools • Broken tools {{}} | |

The Superbox CNC Router (aka CNC Mill) is a versatile tool that can cut a wide variety of materials. The machine has 3 degrees of freedom meaning that unlike the Laser Cutter, which can only cut 2D Shapes, the CNC Mill can carve shapes in 3 dimensions if you can provide the tool paths to drive it. It does not require an induction to use, but help is available if you need it! Contact the #CNC channel on Slack if you need help.

We operate a bring-your-own-bits policy for this machine due to the high likelihood of broken tools. Links to buy tools are available on the Suppliers page.

Overview

| Parameter | Value | ||

|---|---|---|---|

| Working Area | X | Y | Z |

| 348mm | 350mm | 115mm (150mm Z Travel but only unto 90mm Y overhang) | |

| Maximum Feed Rate | 2000mm/min | ||

| Spindle | Kress 1050 FME | ||

| Control Software | LinuxCNC | ||

| Control Interface | Gmoccapy | ||

| Control Hardware | Superbox 2.8 | ||

Software

LinuxCNC, with the Gmoccapy interface, is the control software that we use to drive the tool. There is a dedicated computer hooked up to the machine for this purpose.

LinuxCNC reads G-Code in the .ngc format. You can use any CAM (Computer Aided Manufacture) package you like to create G-Code at home or on the computer opposite.

Slightly older video about Gmoccapy but might be useful to familiarize yourself: https://www.youtube.com/watch?v=O5B-s3uiI6g&t=219s

Y Axis

The machine has a dual Y axis stepper setup, where two stepper motors at either side are used to drive the Y axis. The machine is therefore using a development version of LinuxCNC 2.8. The Y axis is also fitted with two stops, the second of which was designed and added by the hackspace to help in keeping the Y axis homing square to the X axis.

Spindle

The Spindle is a Kress 1050 FME. Its speed is manually controlled via the black dial on the top. It is a good idea to set the spindle speed whilst the spindle is stopped to minimize the operator reaching over the moving machine.

Power to the spindle is controlled via LinuxCNC during operation; It will spin up once it recieves a G-Code command to start it. There is a slide switch on the side of the spindle that should be left on at all times. If it is turned off the tool will simply crash into the work piece without cutting.

| Dial | RPM |

|---|---|

| 1 | 10,000 |

| 2 | 12.600 |

| 3 | 17,000 |

| 4 | 21,000 |

| 5 | 25,000 |

| 6 | 29,000 |

There is a spindle lock button to aid with tool and collet changes

Collets

We have the following collets available, currently stored underneath the monitor for the CNC Computer.

| 1/8" (3.175mm) |

| 4mm |

| 6mm |

| 8mm |

| 10mm |

Bed

The bed is made from PT25 profile Aluminium at 375mm wide

This gives slots every 25mm for fixing.

We have a small selection of T-Slot nuts that will slide into these channels to provide clamping anchors. The T-Slot nuts will accept an M6 bolt.

Suitable materials

- Most woods

- Most plastics

- 6082 T6 Aluminium with caution

- Brass with caution

- Others with extreme caution

This machine is best suited to soft materials due to its aluminium frame. Soft woods, such as Pine, can be cut easily with great results. Plywood is a cheap material that can be used to produce simple profiles quickly but is likely to chip if you are doing any moulding operations. Other materials may work with extreme caution; YouTube videos are a good place to start.

If you are planning to cut hard materials, have a couple of spare tools to hand as you will no doubt break one. Also, do not underestimate the amount of time it will take to clean the machine after the cut. Please leave the machine as you would like to find it.

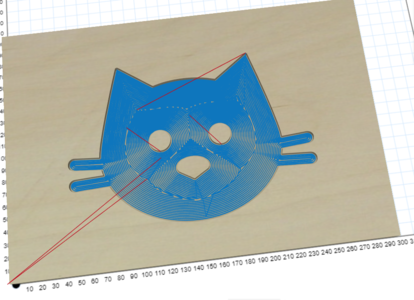

Generating G-Code

To control the tool you will need to feed it instructions. This is done through G-Code! There are more than a few options available for generating G-Code. Each has different pros & cons and each requires a different set of skills to operate.

For Beginners

Inventables' Easel is a 2.5D online CAM package that has a friendly GUI and only requires two small alterations to the code to enable it to function with our machine.

For Enthusiasts/ Advanced Users

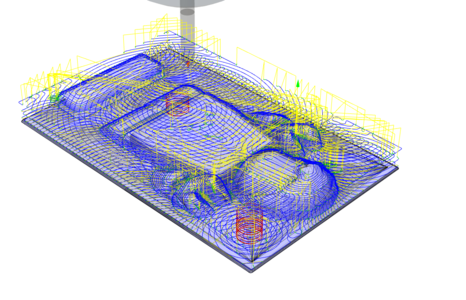

Fusion 360 is a great free software package that has tons of CAM functionality built in. Once you have set up your tool paths using the CAM tools in Fusion you can export the setup using the "LinuxCNC (EMC2) / linuxcnc" post processor built in to Fusion 360.

A good place to start if you're not sure with CNC programming via Fusion 360 is the NYCCNC Youtube channel.

A model of the Kress Collet Nut is here for use in Fusion 360 CAM as a tool holder.: File:Kress Holder.zip

(Instructions for installing The tool library in Fusion 360 can be found here.)

Modelling the tool holder in CAM can aid visualisation and help prevent collisions between the collet nut and workholding, if the workholding is also modelled.

If you want to understand what each line in your program does, refer to the LinuxCNC "G-Code" Quick Reference.

NC Viewer is a useful website to plot programs and analyse them line-by-line.

File Structure

A typical G-Code file might look like this. This may be useful if you want to understand what modifications you need to do to make your program run.

% (My Awesome Part) G90 G94 G17 G21 G0 G53 Z0 M3 S1 -axis movements to cut part- M3 S0 G0 G53 Z0 M30 %

A breakdown is below.

We give the machine a number of 'sanity' gcodes at the start of the program to ensure parameters are correct.

We then give commands to start the spindle, and safely move to the start of the cut.

At the end, we give the machine commands to leave the cut, turn off the spindle and end the program.

% |

Standard starting character |

(My Awesome Part) |

You can add Comments to your file! |

G90 G94 G17 G21 |

Sanity G-Codes (absolute positioning, units per minute, select XY plane, units in mm) |

G0 G53 Z0 |

Rapid move to top of Z travel |

M3 S1 |

Start Spindle (speed set on dial, rpm value here may be useful as reminder, though) |

G54 |

Use G54 Coordinate system, sanity G-Code |

-axis movements to cut part-

M3 S0 |

Stop Spindle |

G0 G53 Z0 |

Rapid move to top of Z travel |

M30 |

Program End |

% |

Standard ending character |

In addition, a feedrate must be declared at the top of the file before a G1 command (move with a specified feedrate, used for cutting) can be used.

To do this, add a line before and use this to declare a feedrate. F1500 means a feedrate of 1500mm per minute.

Operation Instructions

Safety

This is a dangerous tool and should be treated as such. Your safety is your own responsibility. As a guideline, you should wear as a minimum:

- Safety Glasses

- Flying Chips, Broken Tools & loose workpieces are all possibilities

- Ear Defenders

- This machine is seriously loud, you must sit very near to it to monitor the job while it’s running and it’s not uncommon for a cutting cycle to be 30 minutes or longer. Hearing damage is a very real risk. Make sure you also warn others in the CNC room of this too.

Loading your tool

When loading your tool you need to ensure that as much of the shank is contained within the collet as possible. The only exception to this rule is if the job you are running requires a deep cut; then you will need the tool to stick out further.

The video below shows how to load a tool:

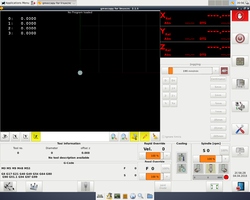

Turn on

Turn on the monitor, PC and Control box

The PC should auto boot into linux and automatically log in to the nottinghack account, if not the password is hackspace

Once in you should see the following desktop, click on the Launch CNC icon to start LinuxCNC

-

1. Turn on the PC & Control Box

-

2. Click 'Launch CNC' (Penguin Icon)

-

3. Your should now see the

Gmoccapyinterface to LinuxCNC

Emergency Stops

Make sure the physical eStops have been cleared by twisting them and check that the eStop light on the control box is out.

Reset The linuxCNC software eStop by clicking the red hand icon in the top right corner.

Turn on the machine in the software by clicking the power button just below the software eStop.

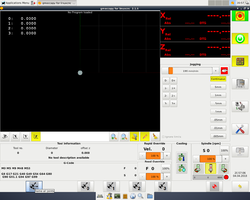

The Interface should look like this:

-

4. Software ready to home

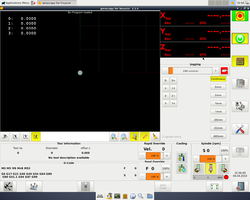

Homing

The machine starts-up in joint mode, as it is not yet homed. It is not possible to jog the axes or otherwise use the machine until you have homed it.

To home the machine, first open the Home menu click the icon in the bottom left corner of the interface. (Target and three arrows). In the bottom menu now click the Home all Icon (far left)

LinuxCNC automatically switches to world mode once all the joints have been homed, and the machine should now be ready to go.

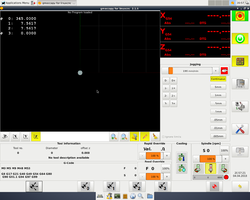

-

5. Open the Homing menu (Target and three arrows icon)

-

6. Home all joints

-

7. Machine ready to go

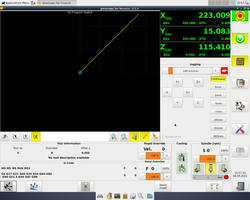

Loading G Code

After you have homed the machine using the instructions above, Click "Enter auto mode to run programs" on the right hand side menu.

On the bottom row of icons you will see a folder icon. Click this to navigate to your ".ngc" G-Code file (the default location is JARVIS).

-

8. Enter Auto Mode

-

9. Browse to G-Code file

Setting Zero

G54 is a coordinate system that is offset from the machine coordinate system. I.e. when you set a position as zero in G54, the CNC is storing this zero position as offsets in X, Y, Z from the machine's origin.

It is used to tell the CNC software where you have secured your workpiece to the table (Set Zero), so it needs to be set before any program is run! The position of the G54 origin should match the origin in your CAM software.

To set it,

- Enter Manual Jogging mode by pressing the appropriate button on the right hand side or pressing F3 on the keyboard.

- Open the probing menu by clicking on the blue icon at the bottom.

- Use the control arrows to move the gantry so that the centre of the tool is sitting on the point where (X,Y,Z) is (0,0,0) on your CAD model. It is easier to probe one datum at a time. E.g. X, then Y, then Z

- On the bottom bar, press "X=?", "Y=?" OR "Z=?" depending on the direction you have probed and set the zero point.

Accounting for the diameter of the tool can be done by typing in half the tools diameter into the probing menu box. Check its right before running any G-Code by jogging the tool to X=0, Y=0 at a safe Z height; the centre axis of the tool should be over the datum point.

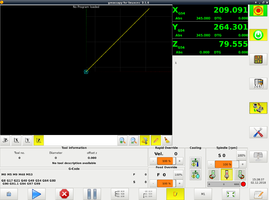

If everything has been set correctly, you should see the preview of your G-Code shift to the correct location.

Running a job

Once G54 is set and the code is loaded simply press the Play button located in the "Auto Mode" menu. Don't leave the job unattended and be ready with the Hoover as a lot of sawdust can be produced.

Example Projects

If you have a project that uses this tool please add it to this list. It would be great to see what other people are using the CNC Mill for!

-

Han Solo in Carbonite CNC

-

Les Plywood Tune-O-Matic Bridge Hardware

-

CNC Workshop for Beginners

-

WW2 Prop Gold

-

CNC Tool Storage

-

Flip Milled Makercoin

-

CNC UK Heightmap

Maintenance

Occasionally the CNC Router will break down and require maintenance. If you're not sure who to ask for help, the #CNC Slack group is the right place to go.

Some maintenance notes are recorded on the wiki here: Superbox CNC Router Maintenance includes information about replacing the Super Box's fuse.

See also

- CNC Workshop for Beginners - workshop designed and run by Dan Spencer

- Suppliers - Milling

- Contour ShuttleXpress - Pendant Jog Shuttle

- New CNC PC Pledge - successful pledge drive for better computer