Metalworking Area: Difference between revisions

No edit summary |

sub-locations |

||

| Line 57: | Line 57: | ||

*[[Startrite Bandsaw]] - Blade Needs replacing - March 2019 | *[[Startrite Bandsaw]] - Blade Needs replacing - March 2019 | ||

<!--Start Sub-location Block --> | |||

<!-- The block between these two comments is used to detect when an area has Sub Locations associated with it--> | |||

<!-- If a Sub-location exists, the boilerplate will automatically add a section with a link to the locations.--> | |||

{{#ifexist:Category:Sub-Location of {{PAGENAME}} | |||

| ==Sub-Locations== | |||

Contained within this area are sub locations. A full list of these can be found here: | |||

[[:Category:Sub-Location of {{PAGENAME}}|Sub-Locations of {{PAGENAME}}]] | |||

| }} | |||

<!--End Sub-location Block--> | |||

==See also== | ==See also== | ||

Revision as of 13:03, 5 March 2019

| Metalworking Area | |

|---|---|

| |

| Intended Use | Working on Metalworking projects |

| Team | Metalworking |

| Floor | Upstairs |

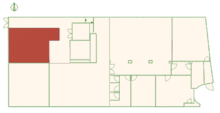

| Map |  |

| Locations: all pages {{}} | |

| This page is a draft and is probably being actively worked on. Feel free to contribute, or make suggestions on the talk page. However, be aware that details are subject to change. (This page was last edited 5 March 2019 @ 13:03 GMT) |

The Metalworking Area contains tools for cutting, drilling, turning, filing, bending and otherwise working with metal; many can also be used for working with plastics. The area is looked after by the Metalworking team.

Tools and equipment

Tools available in this area include:

Tools available in this area include:

A list of tools in this area with wiki pages is available here: Tools and Equipment in Metalworking Area

There are many more tools, particularly metrology & hand tools, that are not listed on the wiki. If you are knowledgeable about something that isn't listed please consider creating a page for the tool.

Important notes

Tools in this area should always be returned to the area after use.

Safety

Please see Nottinghack Rules/Guide - Rule 0: Do Not Be On Fire

Please see Nottinghack Rules/Guide - Rule 0: Do Not Be On Fire

A lot of the machines in this area are dangerous with the potential to cause significant harm. Your safety is your own responsibility.

When working with heavy equipment such as Machine Vices or large projects, Steel toe cap boots are recommended but not required.

When using machines that have spinning parts:

- Remove loose clothing, necklaces or lanyards

- Do not wear gloves or long sleeves

- Protect your eyes with safety glasses

Other equipment such as the Welders require:

- Welding Mask

- Welders Gloves

Availability

This area, or the tools in it does not require booking and can not be booked.

This area, or the tools in it does not require booking and can not be booked.

Cleaning and maintenance

| Please improve this page by adding a photo. The specific reason is: Pic of shop vac needed. Click to upload an image, help with using images can be found here. The talk page may contain suggestions about suitable images. (March 2019) |

Always leave the area as you would like to find it. Build time into your schedule for cleaning up.

There is a shop vac in the area that can be used for removing swarf from large machines and the floor. For small cleaning jobs there is a dust pan and brush located on the wall above the Metalwork Area Tray Store.

Once a month the tools are checked and maintenance carried out as required.

Problems and issues

If there is a problem in the Metalworking Area contact the Metalworking team. If a tool is broken or damaged, report it to the team.

If there is a problem in the Metalworking Area contact the Metalworking team. If a tool is broken or damaged, report it to the team.

The current issues and things not working in this area are as follows.

- Startrite Bandsaw - Blade Needs replacing - March 2019

Sub-Locations

Contained within this area are sub locations. A full list of these can be found here: Sub-Locations of Metalworking Area

See also

| Locations | |||||||

|---|---|---|---|---|---|---|---|

| Upstairs | Comfy Area • Studio • Members Storage • Textiles Workshop • Kitchen • Toilets • Workshop • Dusty Area • Metalworking Area • Spray Booth • Laser Area • CNC Area • Screen Printing | ||||||

| Downstairs | 3D Printer Area • Electronics Area • Blue Room • Team Storage • Metalworking Downstairs • Members Storage Downstairs • Classroom • Bike Area • Main Corridor • CNC Corridor | ||||||

Changes in Category:Metalwork List of abbreviations:

8 December 202528 October 2025

| |||||||